randomly won't idle?

#1

Junior Member

Thread Starter

Join Date: Nov 2001

Location: Shakopee, MN, USA

Posts: 71

Likes: 0

Received 0 Likes

on

0 Posts

Car: '88

Engine: 305tpi

Transmission: t-5

randomly won't idle?

I have an '88 GTA with the 305tpi and T-5. It almost always requires me to press the accelerator in order to start it. Now, sometimes when it starts its fine. However, half the time it won't idle, and the only way to keep it running is to press on the gas at all times! As soon as I let my foot off, it dies almost instantaneously.When it does this, what works sometimes is to let it warm up a little, then let it kill, put the ignition key to "Off", then restart it, and its fine!  Whats going on? It feels like its not sparking or something, and so I put in new plugs and ignition module, which did nothing. Also new is O2 sensor and fuel pressure regulator gasket, cause that had blown-out.

Whats going on? It feels like its not sparking or something, and so I put in new plugs and ignition module, which did nothing. Also new is O2 sensor and fuel pressure regulator gasket, cause that had blown-out.

Whats going on? It feels like its not sparking or something, and so I put in new plugs and ignition module, which did nothing. Also new is O2 sensor and fuel pressure regulator gasket, cause that had blown-out.

Whats going on? It feels like its not sparking or something, and so I put in new plugs and ignition module, which did nothing. Also new is O2 sensor and fuel pressure regulator gasket, cause that had blown-out.

#3

Senior Member

Join Date: Jun 2000

Location: Palm Bay, FL

Posts: 781

Likes: 0

Received 0 Likes

on

0 Posts

Car: 2007 Corvette Z06

Engine: LS7

Transmission: 6 speed

Got to love that MAF sensor.

Isn't it fun slowing down pushing all three pedles at once. I have the same problem now, and had the same problem about 18 months ago, new MAF fixed it, but I think new system like speed density is going to fix it this time. Try unplugging your MAF sensor and see if it will idle with the check engine light.

Isn't it fun slowing down pushing all three pedles at once. I have the same problem now, and had the same problem about 18 months ago, new MAF fixed it, but I think new system like speed density is going to fix it this time. Try unplugging your MAF sensor and see if it will idle with the check engine light.

#4

Supreme Member

Join Date: Aug 2001

Location: Warwick,RI

Posts: 1,236

Likes: 0

Received 0 Likes

on

0 Posts

Car: 88 IROC-Z/00 GTP/05 VUE Redline

Engine: LB9 305/3800 SC/3.5 SOHC V-TEC

Transmission: A4/A4/A5

When is the last time your throttle body was cleaned? My car did that to me at one point in time and i cleaned out the throttle body and it never did it again.

#5

Junior Member

Thread Starter

Join Date: Nov 2001

Location: Shakopee, MN, USA

Posts: 71

Likes: 0

Received 0 Likes

on

0 Posts

Car: '88

Engine: 305tpi

Transmission: t-5

How do I check the IAC? With a voltometer? If so does anyone know where I could find out how many volts each circuit should put out? And should I clean the TB with carb cleaner by scrubbing out the barrels? I sure hope its not the MAF cause thats the most expensive, but I kindof have a hunch that it is... Because the computer gave me trouble code 36, which is "MAF burnoff circuit problem", or "extra or missing pulses in EST" And it also is running at about 11mpg, which is NOT right for a 305tpi.

#6

Supreme Member

Join Date: Apr 2002

Location: Austin

Posts: 1,353

Likes: 0

Received 3 Likes

on

3 Posts

Car: 82 Z-28

Engine: 383 TPI

Transmission: 700R4

11 mpg doesn't sound like an intermitent IAC problem.

Can't check an IAC with a voltmeter. It uses pulse width modulation (or something like that). You need a special hand-held gizmo that costs way too much off the Snap-on truck.

The gizmo will allow you to electrically toggle the plunger in and out. Toggle it too far out and POW, off goes the plunger at the speed of light. It must have been traveling at the speed of light, I couldn't see where it went.

I don't know a lot abt the MAF sensors, but the code 36 is suspecious.

Does the code come back right away after resetting the computer?

Can't check an IAC with a voltmeter. It uses pulse width modulation (or something like that). You need a special hand-held gizmo that costs way too much off the Snap-on truck.

The gizmo will allow you to electrically toggle the plunger in and out. Toggle it too far out and POW, off goes the plunger at the speed of light. It must have been traveling at the speed of light, I couldn't see where it went.

I don't know a lot abt the MAF sensors, but the code 36 is suspecious.

Does the code come back right away after resetting the computer?

#7

Junior Member

Thread Starter

Join Date: Nov 2001

Location: Shakopee, MN, USA

Posts: 71

Likes: 0

Received 0 Likes

on

0 Posts

Car: '88

Engine: 305tpi

Transmission: t-5

Today I unplugged the MAF, visually inspected the filament, (which looked fine), and put it back in. The car took about 6 seconds of starting to fire up, and then I took it for about a 30min tops-down cruise, and it was perfect.  Still sound like a faulty MAF? I'm a couple days away from just taking it in and forking over my entire paycheck!

Still sound like a faulty MAF? I'm a couple days away from just taking it in and forking over my entire paycheck! Is there a way to know for sure if the MAF is bad? Can I take it somewhere and have it tested?

Is there a way to know for sure if the MAF is bad? Can I take it somewhere and have it tested?

Still sound like a faulty MAF? I'm a couple days away from just taking it in and forking over my entire paycheck!

Still sound like a faulty MAF? I'm a couple days away from just taking it in and forking over my entire paycheck! Is there a way to know for sure if the MAF is bad? Can I take it somewhere and have it tested?

Is there a way to know for sure if the MAF is bad? Can I take it somewhere and have it tested? Trending Topics

#8

Supreme Member

Join Date: Apr 2002

Location: Austin

Posts: 1,353

Likes: 0

Received 3 Likes

on

3 Posts

Car: 82 Z-28

Engine: 383 TPI

Transmission: 700R4

Did ya check the elec connections at the MAF?

Since it started running good after removing and re-installing the MAF. I would suspect the elec connector.

Don't know of any way to test them, other than replacing them.

Since it started running good after removing and re-installing the MAF. I would suspect the elec connector.

Don't know of any way to test them, other than replacing them.

#9

Eric,

I doubt that you have a problem with the MAF itself. The ECM monitors the MAF very closely, and will lock an error code if the MAF reports an intake air flow that is out of the acceptable range for more than 600mS. That's faster than the Vikings can choke in the playoffs... (Yeah, I'm an ignorant Cheddar-Header.) If the MAF hot wire is not burned clean in the burn off cycle on engine shut down, it can under report the intake air flow. This would eventually set a code 34 as well.

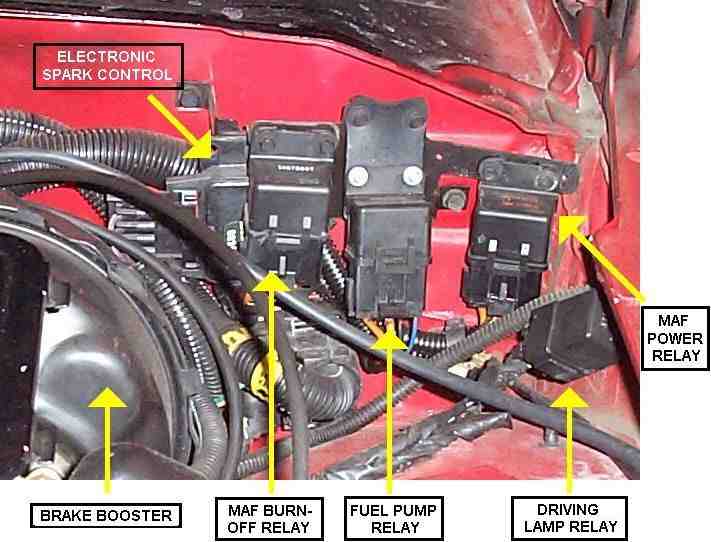

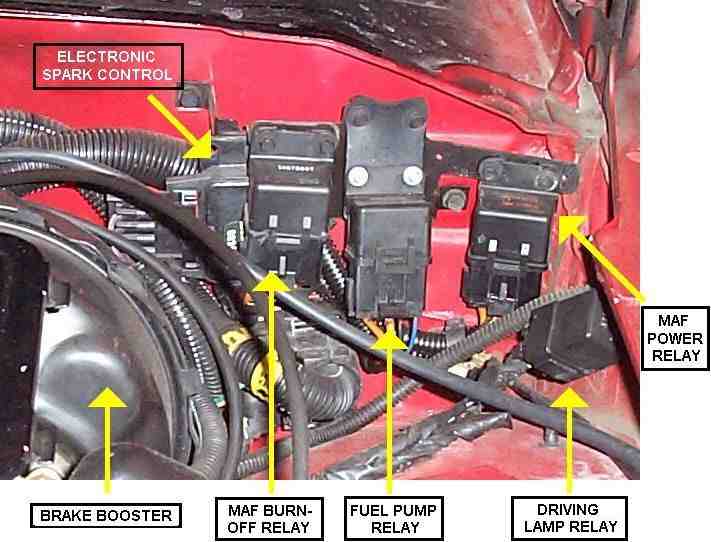

Your problem can be isolated fairly easily. Inspect the MAF burn off relay and the connector on it. Inspect the connector at the MAF as well. You can exchange the MAF power and burn off relays to help isolate the problem.

Exchange the relays, then start the engine, allow it to run for a minute or so, and shut it off. The next time you start the engine you should generate either a code 33, 34, or the 36 again. If the code is still the 36, the relays are good, and the problem could be with either the connections at the relay or MAF. If the error code changes to either a 33 or 34, the relay is toast. You can usually get a replacement relay for about $10.00.

There are some rare conditions that can cause the burn off cycle to be interrupted by the auxiliary oil pressure switch, but that shouldn't be a concern at this point - it's really a freak occurrence.

As for the idle quality problems, the cause is most likely a dirty IAC and throttle body, and possibly a TPS voltage setting that is out of spec. Incidentally, the IAC is not a sensor (input device), but a load device (stepper motor). You can test the IAC itself with an ohmmeter, but the operating coils seldom fail. Diagnosing the ECM signals to the IAC requires either a specialized tester as described, or a dual-trace oscilloscope to monitor the phasing of the ECM current pulse outputs. Generally, the ECM has no trouble controlling the IAC and seldom fails, so you can probably disregard those possibilities for now as well.

Cleaning the IAC is probably a really good start. It doesn't take a lot of contamination to lock up an IAC motor:

Since this post is getting as long as a Tolstoy novel, I'll post another reply with IAC, throttle body, and TPS instructions. (We have limited message length, you know.) That should get you closer to aa better idle and possibly easier starts.

I doubt that you have a problem with the MAF itself. The ECM monitors the MAF very closely, and will lock an error code if the MAF reports an intake air flow that is out of the acceptable range for more than 600mS. That's faster than the Vikings can choke in the playoffs... (Yeah, I'm an ignorant Cheddar-Header.) If the MAF hot wire is not burned clean in the burn off cycle on engine shut down, it can under report the intake air flow. This would eventually set a code 34 as well.

Your problem can be isolated fairly easily. Inspect the MAF burn off relay and the connector on it. Inspect the connector at the MAF as well. You can exchange the MAF power and burn off relays to help isolate the problem.

Exchange the relays, then start the engine, allow it to run for a minute or so, and shut it off. The next time you start the engine you should generate either a code 33, 34, or the 36 again. If the code is still the 36, the relays are good, and the problem could be with either the connections at the relay or MAF. If the error code changes to either a 33 or 34, the relay is toast. You can usually get a replacement relay for about $10.00.

There are some rare conditions that can cause the burn off cycle to be interrupted by the auxiliary oil pressure switch, but that shouldn't be a concern at this point - it's really a freak occurrence.

As for the idle quality problems, the cause is most likely a dirty IAC and throttle body, and possibly a TPS voltage setting that is out of spec. Incidentally, the IAC is not a sensor (input device), but a load device (stepper motor). You can test the IAC itself with an ohmmeter, but the operating coils seldom fail. Diagnosing the ECM signals to the IAC requires either a specialized tester as described, or a dual-trace oscilloscope to monitor the phasing of the ECM current pulse outputs. Generally, the ECM has no trouble controlling the IAC and seldom fails, so you can probably disregard those possibilities for now as well.

Cleaning the IAC is probably a really good start. It doesn't take a lot of contamination to lock up an IAC motor:

Since this post is getting as long as a Tolstoy novel, I'll post another reply with IAC, throttle body, and TPS instructions. (We have limited message length, you know.) That should get you closer to aa better idle and possibly easier starts.

Last edited by Vader; 03-31-2018 at 10:07 PM. Reason: Updaed links

#10

As promised:

Idle Air Control Cleaning

You can remove the IAC and service it. Remove the electrical connector from the IAC. Unscrew the IAC unit from the throttle body.

You can gently rock the pintle back and forth and allow the spring to extend it until it comes apart in your hands. Clean everything with lint-free cloths and a mild solvent. Harsh solvents can affect the insulation of the stepper motor coils. It's generally the dirt and buildup on this worm shaft that causes sluggish IAC operation.

When the worm gear on the pintle shaft is clean and dry, apply one drop of clean light oil to the shaft and work the pintle back into the rack gears of the motor by the same rocking motion. It takes a while to get the pintle back into the worm gears, but you'll get it. It is important to get the pintle fully retracted into the housing so that the pintle is not forced against the gears when reinstalling the IAC unit in the throttle body.

While the IAC is out, clean the air passages in the throttle body. The orifice in the TB where the IAC resides is the seat that the IAC valve closes against, and it can accumulate a lot of carbon, dirt, and debris. The easy way to do this is with carburetor cleaner and a small stiff brush.

When everything is clean and dry, replace the gasket if it is damaged, apply a little anti-seize to the threads, and torque the IAC to the proper specs. (13 ft/lb for '85-'89 , 30 in/lb for 1990-on.) Proceed with setting the TPS and minimum air position.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Throttle Minimum Air Position Adjustment

Tools needed:

1. Torx driver # T-20

2. Paper Clip

3. Small Punch

4. Tachometer

GENERAL NOTE: The engine should be at normal operating temperature before performing any adjustments. Never rely on the dash mounted instruments for diagnostics and adjustments. The oil pressure and temperature gauges and the voltmeter and tachometer just aren't calibrated accurately enough for diagnosis, but are a relative indication for monitoring the vehicle while driving.

For this adjustment, the transmission will be in DRIVE while you're under the hood. You will need to securely set the parking brake and block the drive wheels. It would also be a good idea to have an assistant hold the service brakes while you perform the adjustments.

In order to successfully complete the adjustment, the IAC air passages and pintle need to be clean. The throttle plates and bores need to be clean as well. If this is not the case, you'll need to remove the air cleaner from TBI engines or the intake air bellows from TPI engines to gain access to the area to be cleaned. A spray-type carburetor cleaner works well for this. Cleaning the IAC passages on a TPI/MAF engine will set a DTC, but we'll be clearing that later. With the engine idling, direct the spray cleaner into the IAC air passages and around the throttle plates. Shut off the engine and continue cleaning the throttle plates by opening the throttle manually. Once everything is satisfactorily cleaned, replace the air bellows on TPI engines. Many times, this alone can solve IAC/idle speed problems.

If this doesn't solve the problem, you may need to remove and clean the IAC stepper motor. If the IAC appears to be clean and functioning properly, continue with the adjustment procedure.

Locate the Assembly Line Diagnostic Link connector under your dash panel. Remove the cover if it is still there.

Cut and form a paper clip into a "U" shape. Insert the clip ends into the ALDL in the 'A' and 'B' sockets.

Turn on the ignition, but DON'T start the engine. This will force the ECM into its diagnostic mode. Wait 30 seconds to allow the IAC pintle to fully extend. With the ignition still on, go under the hood, remove the electrical connector from the IAC, then turn off the ignition and remove the paper clip jumper from the ALDL. With the IAC pintle fully extended (closed) all idle air will be controlled by the position of the throttle plates. Some manuals indicate that the EST bypass connector should be disconnected for this procedure, while some make no mention of it. While timing is a factor in idle speed, the EST should only operate as a function of engine RPM, temperature, and detonation sensor inputs. To remove all doubt, disconnect the EST bypass connector is your car is so equipped. Some TBI and V-6 engines do not have this bypass connector, and therefore must be set with no regard to the EST system. The EST can be bypassed on some cars by grounding the diagnostic terminal at the ALDL and continuing with the procedure, but the fuel mixture will be skewed to the rich side, affecting idle speed as well. In any event, the minimum air position idle speed range is wide enough to allow for some variations. As always, it is best to consult your service manual for the exact procedure for your system.

Locate the Torx screw on the left side of the throttle body. It may be equipped with a protective metal cap from the factory. This was intended to discourage adjustment. If the cap is present, use a small punch to knock it out. Once the screw is accessible, start the engine and place the transmission in DRIVE. Adjust the throttle stop to obtain 400-450 RPM with the transmission in "DRIVE" on an automatic transmission car, 450-550 in neutral on a manual transmission car, rotating the Torx screw clockwise to raise speed and counter-clockwise to lower speed. Once the idle RPM is set, place the transmission in PARK and turn off the engine.

Re-connect the electrical connector onto the IAC. Start engine. Idle speed should be governed by the ECM at approximately 600-650 rpm in "DRIVE" (for unmodified cars). Idle speed in NEUTRAL or PARK is less significant, and will be higher.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Throttle Position Sensor (TPS)

Tools needed:

1. Digital Volt-Ohm-Meter (VOM)

2. Breakout jumper wires or probes (make your own)

3. AutoXray, Diacom, or similar scanner will replace the VOM and jumper wires.

Turn on ignition, but don't start the engine.

With a diagnostic scanner: plug in the scanner and read the TPS voltage. It should be 0.54Volts +/- 0.07 VDC.

Connect the VOM to the TPS electrical connector terminals ‘A' and ‘B'.

With a breakout jumper: Disconnect the electrical connector from the TPS. Install the breakout in-line, between the TPS and wiring harness connector. Connect the meter probes to terminals 'A' and 'B' on the connector. (‘B' is the positive connection, ‘A' the signal ground, or negative.)

With probes: If you have very slender probes on your VOM, you can back-probe the TPS connector while it is attached to the TPS. If you have made probes of large dressmakers pins or a similar item, you can back-probe the connector as well. Connect the meter probes to terminals 'A' and 'B' on the connector.

Turn on the ignition to read the TPS output voltage at the idle position. The reading should be 0.54VDC +/- 0.07VDC. The ideal is the center of the range, 0.54VDC for a stock engine. To adjust the output voltage, loosen the two Torx screws holding the TPS to the throttle body, and slightly rotate the TPS up or down, reading the voltage until it comes into specification. Tighten screws. Using the throttle lever, rotate the throttle to WOT (wide open throttle). The TPS voltage should be over 4.0 volts. Close the throttle again, and then slowly open it to WOT, observing the voltage reading. It should increase progressively and in a linear fashion. If it sticks or jumps or falls off at all while doing this check, the TPS sensor may be failing and could be a cause of stumbling and driveability problems.

After achieving the desired setting, turn off the ignition switch. Remove all jumpers or the scanner and reconnect the TPS connector as required.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Reinitializing the ECM

If you set a DTC during the procedure, the SES light should be illuminated on the dash. This ECM retains DTC data for the previous 50 engine starts, so the codes will eventually be cleared. If you want more immediate results, after shutting down the engine disconnect the negative battery terminal for five minutes. This will clear the ECM of all diagnostic trouble codes. Clearing the ECM also clears any data learned about your engine, and clears the radio presets. If you have a Delco-Loc or Theft Loc II radio, make sure you follow the procedure to unlock the radio protection before disconnecting the battery. This five minutes is also just about long enough to clean both battery cables. Reconnect the battery. When you first start the engine after clearing the ECM, the engine will operate with base parameters programmed into the ECM PROM. These parameters may not be optimum for your engine, but the ECM will enter a Block Learn Mode soon after the engine is warm and enters Closed Loop Mode. The ECM will write new data tables specific to your engine and will eventually rely on those tables instead of the base tables of the factory program. You can expedite this process by driving the car for 20 minutes under varying conditions to allow the ECM to initialize. Or you can wait and drive the car normally at your convenience. The BLM tables are constantly being updated as sensor input ranges change, but the greatest change will occur within the first twenty minutes of Closed Loop operation.

Idle Air Control Cleaning

You can remove the IAC and service it. Remove the electrical connector from the IAC. Unscrew the IAC unit from the throttle body.

You can gently rock the pintle back and forth and allow the spring to extend it until it comes apart in your hands. Clean everything with lint-free cloths and a mild solvent. Harsh solvents can affect the insulation of the stepper motor coils. It's generally the dirt and buildup on this worm shaft that causes sluggish IAC operation.

When the worm gear on the pintle shaft is clean and dry, apply one drop of clean light oil to the shaft and work the pintle back into the rack gears of the motor by the same rocking motion. It takes a while to get the pintle back into the worm gears, but you'll get it. It is important to get the pintle fully retracted into the housing so that the pintle is not forced against the gears when reinstalling the IAC unit in the throttle body.

While the IAC is out, clean the air passages in the throttle body. The orifice in the TB where the IAC resides is the seat that the IAC valve closes against, and it can accumulate a lot of carbon, dirt, and debris. The easy way to do this is with carburetor cleaner and a small stiff brush.

When everything is clean and dry, replace the gasket if it is damaged, apply a little anti-seize to the threads, and torque the IAC to the proper specs. (13 ft/lb for '85-'89 , 30 in/lb for 1990-on.) Proceed with setting the TPS and minimum air position.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Throttle Minimum Air Position Adjustment

Tools needed:

1. Torx driver # T-20

2. Paper Clip

3. Small Punch

4. Tachometer

GENERAL NOTE: The engine should be at normal operating temperature before performing any adjustments. Never rely on the dash mounted instruments for diagnostics and adjustments. The oil pressure and temperature gauges and the voltmeter and tachometer just aren't calibrated accurately enough for diagnosis, but are a relative indication for monitoring the vehicle while driving.

For this adjustment, the transmission will be in DRIVE while you're under the hood. You will need to securely set the parking brake and block the drive wheels. It would also be a good idea to have an assistant hold the service brakes while you perform the adjustments.

In order to successfully complete the adjustment, the IAC air passages and pintle need to be clean. The throttle plates and bores need to be clean as well. If this is not the case, you'll need to remove the air cleaner from TBI engines or the intake air bellows from TPI engines to gain access to the area to be cleaned. A spray-type carburetor cleaner works well for this. Cleaning the IAC passages on a TPI/MAF engine will set a DTC, but we'll be clearing that later. With the engine idling, direct the spray cleaner into the IAC air passages and around the throttle plates. Shut off the engine and continue cleaning the throttle plates by opening the throttle manually. Once everything is satisfactorily cleaned, replace the air bellows on TPI engines. Many times, this alone can solve IAC/idle speed problems.

If this doesn't solve the problem, you may need to remove and clean the IAC stepper motor. If the IAC appears to be clean and functioning properly, continue with the adjustment procedure.

Locate the Assembly Line Diagnostic Link connector under your dash panel. Remove the cover if it is still there.

Cut and form a paper clip into a "U" shape. Insert the clip ends into the ALDL in the 'A' and 'B' sockets.

Turn on the ignition, but DON'T start the engine. This will force the ECM into its diagnostic mode. Wait 30 seconds to allow the IAC pintle to fully extend. With the ignition still on, go under the hood, remove the electrical connector from the IAC, then turn off the ignition and remove the paper clip jumper from the ALDL. With the IAC pintle fully extended (closed) all idle air will be controlled by the position of the throttle plates. Some manuals indicate that the EST bypass connector should be disconnected for this procedure, while some make no mention of it. While timing is a factor in idle speed, the EST should only operate as a function of engine RPM, temperature, and detonation sensor inputs. To remove all doubt, disconnect the EST bypass connector is your car is so equipped. Some TBI and V-6 engines do not have this bypass connector, and therefore must be set with no regard to the EST system. The EST can be bypassed on some cars by grounding the diagnostic terminal at the ALDL and continuing with the procedure, but the fuel mixture will be skewed to the rich side, affecting idle speed as well. In any event, the minimum air position idle speed range is wide enough to allow for some variations. As always, it is best to consult your service manual for the exact procedure for your system.

Locate the Torx screw on the left side of the throttle body. It may be equipped with a protective metal cap from the factory. This was intended to discourage adjustment. If the cap is present, use a small punch to knock it out. Once the screw is accessible, start the engine and place the transmission in DRIVE. Adjust the throttle stop to obtain 400-450 RPM with the transmission in "DRIVE" on an automatic transmission car, 450-550 in neutral on a manual transmission car, rotating the Torx screw clockwise to raise speed and counter-clockwise to lower speed. Once the idle RPM is set, place the transmission in PARK and turn off the engine.

Re-connect the electrical connector onto the IAC. Start engine. Idle speed should be governed by the ECM at approximately 600-650 rpm in "DRIVE" (for unmodified cars). Idle speed in NEUTRAL or PARK is less significant, and will be higher.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Throttle Position Sensor (TPS)

Tools needed:

1. Digital Volt-Ohm-Meter (VOM)

2. Breakout jumper wires or probes (make your own)

3. AutoXray, Diacom, or similar scanner will replace the VOM and jumper wires.

Turn on ignition, but don't start the engine.

With a diagnostic scanner: plug in the scanner and read the TPS voltage. It should be 0.54Volts +/- 0.07 VDC.

Connect the VOM to the TPS electrical connector terminals ‘A' and ‘B'.

With a breakout jumper: Disconnect the electrical connector from the TPS. Install the breakout in-line, between the TPS and wiring harness connector. Connect the meter probes to terminals 'A' and 'B' on the connector. (‘B' is the positive connection, ‘A' the signal ground, or negative.)

With probes: If you have very slender probes on your VOM, you can back-probe the TPS connector while it is attached to the TPS. If you have made probes of large dressmakers pins or a similar item, you can back-probe the connector as well. Connect the meter probes to terminals 'A' and 'B' on the connector.

Turn on the ignition to read the TPS output voltage at the idle position. The reading should be 0.54VDC +/- 0.07VDC. The ideal is the center of the range, 0.54VDC for a stock engine. To adjust the output voltage, loosen the two Torx screws holding the TPS to the throttle body, and slightly rotate the TPS up or down, reading the voltage until it comes into specification. Tighten screws. Using the throttle lever, rotate the throttle to WOT (wide open throttle). The TPS voltage should be over 4.0 volts. Close the throttle again, and then slowly open it to WOT, observing the voltage reading. It should increase progressively and in a linear fashion. If it sticks or jumps or falls off at all while doing this check, the TPS sensor may be failing and could be a cause of stumbling and driveability problems.

After achieving the desired setting, turn off the ignition switch. Remove all jumpers or the scanner and reconnect the TPS connector as required.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Reinitializing the ECM

If you set a DTC during the procedure, the SES light should be illuminated on the dash. This ECM retains DTC data for the previous 50 engine starts, so the codes will eventually be cleared. If you want more immediate results, after shutting down the engine disconnect the negative battery terminal for five minutes. This will clear the ECM of all diagnostic trouble codes. Clearing the ECM also clears any data learned about your engine, and clears the radio presets. If you have a Delco-Loc or Theft Loc II radio, make sure you follow the procedure to unlock the radio protection before disconnecting the battery. This five minutes is also just about long enough to clean both battery cables. Reconnect the battery. When you first start the engine after clearing the ECM, the engine will operate with base parameters programmed into the ECM PROM. These parameters may not be optimum for your engine, but the ECM will enter a Block Learn Mode soon after the engine is warm and enters Closed Loop Mode. The ECM will write new data tables specific to your engine and will eventually rely on those tables instead of the base tables of the factory program. You can expedite this process by driving the car for 20 minutes under varying conditions to allow the ECM to initialize. Or you can wait and drive the car normally at your convenience. The BLM tables are constantly being updated as sensor input ranges change, but the greatest change will occur within the first twenty minutes of Closed Loop operation.

Last edited by Vader; 03-21-2006 at 03:46 PM.

#11

Junior Member

Thread Starter

Join Date: Nov 2001

Location: Shakopee, MN, USA

Posts: 71

Likes: 0

Received 0 Likes

on

0 Posts

Car: '88

Engine: 305tpi

Transmission: t-5

Vader- Thankyou so very much! :hail: That is more help than I could ever have hoped for. I am going to try all this tomorrow when I get up. I'll let ya know how it goes.

#12

Junior Member

Thread Starter

Join Date: Nov 2001

Location: Shakopee, MN, USA

Posts: 71

Likes: 0

Received 0 Likes

on

0 Posts

Car: '88

Engine: 305tpi

Transmission: t-5

I pulled out the IAC, and couldn't get the pin out of the tip, so I bought a new one for $50. I think that fixed it. All today it was just fine. However it still takes a little longer to start than I want. I just put in new spark plugs, and ran injector cleaner through it too, but that didn't help. Could it be plug wires? Or something else? Thanks again Vader for your help.

#13

Eric,

I'm guessing your error code is gone by your last post. It was probably the result os a poor TPS adjustment.

If you haven't done so in the past 20,000 miles or so, it's time for a tune up. You've already done the more difficult part in changing the plugs. The throttle body is clean and TPS and minimum air are now set, so the rest is pretty easy. Obviously, you have a DMM at hand that you used to set the TPS, so you can use it to test the plug and coil wires as well. Expect to measure about 300-500 ohms per foot of length of each of the wires. If the resistance is too high, the wires are breaking down and need replacement. If they test good, clean the end boots with a mild solvent or soap and hot water, then reapply silicone grease to the inside of each boot.

Remove the distributor cap and rotor to inspect for corrosion, carbon streaks, and any cracks. If the terminals show excessive pitting or discoloration, replace the items. While the cap and rotor are out of the way, take a close look at the reluctor and pickup coil in the base of the distributor. Check the reluctor for corrosion and cracks. Inspect the pickup coil for discoloration and cracks. You can unplug the pickup coil connector and measure the resistance of it as well. Between 500-1,500 ohms is acceptable, and about 850 is perfect. Check the resistance of one of the leads to a good ground. You should get no reading whatsoever. If the pickup coil fails any of these tests, replace it.

Once you have a good cap, rotor, adn reliable pickup assembly, the ignition coil can be tested as well. A very low resistance (0.1-1.0 ohms) should be found on the primary side, and 6,000-10,000 ohms on the secondary side. Once you've verified a good coil, the ignition system should be ready to go.

As for the starting, try starting a little more slowly. Turn the ignition on and wait a second or two before cranking to allow the fuel pump to pressureize the system fully. This is also a good opportunity to watch the SES lamp for the single flash that should occur as soon as the ECM is powered on, indicating a good diagnostic self test of the ECM.

It will be interesting to hear what you find.

I'm guessing your error code is gone by your last post. It was probably the result os a poor TPS adjustment.

If you haven't done so in the past 20,000 miles or so, it's time for a tune up. You've already done the more difficult part in changing the plugs. The throttle body is clean and TPS and minimum air are now set, so the rest is pretty easy. Obviously, you have a DMM at hand that you used to set the TPS, so you can use it to test the plug and coil wires as well. Expect to measure about 300-500 ohms per foot of length of each of the wires. If the resistance is too high, the wires are breaking down and need replacement. If they test good, clean the end boots with a mild solvent or soap and hot water, then reapply silicone grease to the inside of each boot.

Remove the distributor cap and rotor to inspect for corrosion, carbon streaks, and any cracks. If the terminals show excessive pitting or discoloration, replace the items. While the cap and rotor are out of the way, take a close look at the reluctor and pickup coil in the base of the distributor. Check the reluctor for corrosion and cracks. Inspect the pickup coil for discoloration and cracks. You can unplug the pickup coil connector and measure the resistance of it as well. Between 500-1,500 ohms is acceptable, and about 850 is perfect. Check the resistance of one of the leads to a good ground. You should get no reading whatsoever. If the pickup coil fails any of these tests, replace it.

Once you have a good cap, rotor, adn reliable pickup assembly, the ignition coil can be tested as well. A very low resistance (0.1-1.0 ohms) should be found on the primary side, and 6,000-10,000 ohms on the secondary side. Once you've verified a good coil, the ignition system should be ready to go.

As for the starting, try starting a little more slowly. Turn the ignition on and wait a second or two before cranking to allow the fuel pump to pressureize the system fully. This is also a good opportunity to watch the SES lamp for the single flash that should occur as soon as the ECM is powered on, indicating a good diagnostic self test of the ECM.

It will be interesting to hear what you find.

#14

Junior Member

Thread Starter

Join Date: Nov 2001

Location: Shakopee, MN, USA

Posts: 71

Likes: 0

Received 0 Likes

on

0 Posts

Car: '88

Engine: 305tpi

Transmission: t-5

Vader- I didn't get a chance to mess with the TPS or the ignition system at all. All I did to get it running well, was replace that IAC motor. I will hopefully get into it more deeply with the ohm meter soon, but I will start a new post for that cause this one is taking too long to load with the pics. I might just take it in for a tune up too. But I would rather do it myself cause I like to learn about that stuff. I do let the fuel pump charge up before I start it, but it still takes its time. It will fire right up if its been off for less than a couple minutes. Any longer than that, and it takes about 4-5 sec. of turning over to start.

#15

Junior Member

Join Date: Jun 2002

Location: Lubbock, TX

Posts: 33

Likes: 0

Received 0 Likes

on

0 Posts

Car: 87 Camaro LT

Engine: 305 4BBL

Transmission: TH700R4

Also check your timing.

I just barely bought my 87 LT a week ago and have been tinkering night and day since then.

Just last night, I got around to kicking up the idle so that I can check the timing without the car dieing on me (in the same situation as you)

Turns out I was -6 and adjusted it to +3 and the car has alot more ***** and runs like a gem... timing seems to always solve my problems (and cause them for that matter)

I just barely bought my 87 LT a week ago and have been tinkering night and day since then.

Just last night, I got around to kicking up the idle so that I can check the timing without the car dieing on me (in the same situation as you)

Turns out I was -6 and adjusted it to +3 and the car has alot more ***** and runs like a gem... timing seems to always solve my problems (and cause them for that matter)

Thread

Thread Starter

Forum

Replies

Last Post

777Shock777

Tech / General Engine

4

10-29-2015 04:30 PM

mdtoren

Tech / General Engine

0

08-16-2015 05:45 PM