Single-stage Nitrous for the 406 with Holley EFI

#1

Supreme Member

Thread Starter

iTrader: (25)

Join Date: Sep 2005

Location: NJ

Posts: 1,816

Received 280 Likes

on

218 Posts

Car: 1987 IROC-Z

Engine: 406 on N20 w/ EFI

Transmission: P.B. 700R4

Axle/Gears: 12 bolt w/ 3.91

Single-stage Nitrous for the 406 with Holley EFI

Those of you who have followed my build thread over the past two years, know that I have always planned on putting a single stage wet nitrous system onto the engine. Here is a link to the build thread in case you want to read it or find all the engine/powertrain/car information. http://www.njfboa.org/forums/showthread.php?t=69033 The goal for this car has always been a naturally aspirate mid-high 11's in the 1/4 mile , and then mid-high 10's on a single stage of nitrous. I am not a bracket racer, just simply a fella chasing a timeslip.

Anyways, the time has come for me to get this going. I am certainly no expert with nitrous, but I did run nitrous on the old 305 TPI engine for about 4 years. It made the 305 fun, but I basically just played around with it on the street, during autocross, and some drag racing. That kit was the NOS Powershot, which had 100 hp jets and 150 hp jets. Here is a link to the kit on Jegs: https://www.jegs.com/i/NOS/741/05151...QaAnd9EALw_wcB

So, I still have everything from this setup, and for my upcoming "version 1" of this upcoming nitrous system, I will be using most of the components. Instead of just drilling the engine with a 200 or 250 shot and having to buy new solenoids, I feel safer using the existing "smaller" solenoids for at least this fall 2021 season. I will be using the existing 10 pound bottle, its blow-down tube, the bottle pressure gauge and the main -4an fed line from the bottle. I also will be using my toggle switch setup that is mounted in the ashtray. I do not yet want a bottle heater, and I will never need a remote bottle opener since I can reach the bottle valve from my drivers seat. As mentioned, the NOS powershot solenoids are good for somewhere in the neighborhood of 150 hp (but I have read 175 can be done) so I will use those, along with the nitrous purge solenoid. I bought a NOS cheater wet-plate from a guy on thirdgen.org for $50 which was a heck of a deal. The wiring, and the relay will all be replaced with fresh new stuff, some colder spark plugs, and a new oxygen sensor with an O2 extender bung is also required. I am on the fence about using a fuel pressure safety switch, because I know it is a good idea, but mounting it in the tight area where I will have the fuel lines just might not work for me. I also do not plan to use a throttle mounted "window" activation switch, as I can control the nitrous both with my shifter mounted button AND also with the holley efi software.

I have been reading a lot about nitrous while using the holley sniper efi and I will get into some of that later. UNsure if I will be doing a progressive shot or not yet; maybe. This post is mostly for me to lay out the components and gameplan for everyone to look at, and then let me know their thoughts and technical opinions.

Bottle:

Use existing 10 pound NOS bottle with blow down tube.

Toggle switches:

Using the existing Nitrous Outlet ash-tray panel. I only plan to use the "master arming switch" and the "purge button". https://nitrousoutlet.com/i-30559860...tch-panel.html

Fuel Pressure safety switch:

undecided currently, but I will Probably get one

https://nitrousoutlet.com/i-30559952...-manifold.html

Oxygen sensor:

The nitrous guys that run the holley efi assure me that I will need a better O2 sensor as well as a special extender. (will add link later)

Lines/Plumbing:

I had used the braided -3an lines that came with the TPI kit on the TPI and they were good. They are way too long for my new setup. Instead of shortening them, I think i want to go with a hardline from the solenoids to the plate. Will do the -an flex lines to connect the fuel system to the solenoid, and to connect the nitrous bottle to the purge solenoid. But everything else I want to do with hardline.

- I am going to have to find a spot I am happy with to mount the solenoids in a spot that not only is visually appealing, but also serviceable and allows me to change jets easily. Therefore, instead of fighting with stainless steel lines at first, I might try to use some of my 3/16" (which is -3an) copper-nickel lines that remains from when I built my brake lines throughout the car. I have emailed Nitrous Express AND Nitrous Solutions who both told me that copper-nickle line is absolutely fine to use for hardline on a nitrous/fuel system. It will be much easier to bend, flare, and work with. However, they will not be shiny silver. If I can get the lines the way I want, maybe later I can re-create them with stainless. I will need to buy the proper fittings, tube nuts, and adapters. I also will need to buy a cheap-o 37degree flare tool, but I do have a tube bender already.

- Fuel line fittings will be needed too to T-off of the existing -8 fuel feed line. I will also re-install my Aeromotive fuel pressure gauge, and probably that fuel pressure safety switch, so it will be a cluttered area of fuel fittings and adapters.

Solenoid Locations/brackets:

This one is tricky, and right now I have about 3 possible options, but feel free to add in your suggestions. Number 1 priority is that the solenoids have to be mounted in a way that are visually appealing to me. I don't want to just have all sorts of brackets in random places with solenoids and lines hanging all over the top of the engine. No way. There are not too many choices that appeal to me, and maybe I could make my own later, but for now, I might use something like these and "drop-mount" them off the carb-mount studs. https://www.holley.com/products/nitr...parts/16523NOS Initially i wanted the solenoids all in that "valley" between the sniper and the thermostat housing. IT will get real tricky to make all the plumbing work that way, so I don't think its a realistic option. Also, the purge solenoid should be very close to the nitrous solenoid, so keep that in mind.

- Nitrous plate:

NOS cheater plate which i got for $50. It is capable of flowing up to a 250 hp wet shot, which is all I ever plan to put to this engine. link: https://www.jegs.com/i/NOS/741/12500...AaAkwmEALw_wcB I will buy some spare 4150 carb gaskets too for fresh gaskets during the install.

Jets:

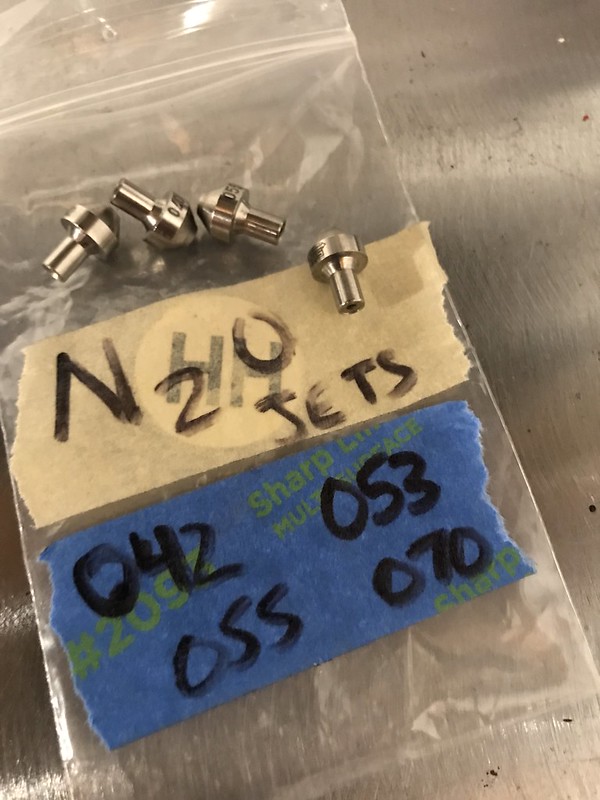

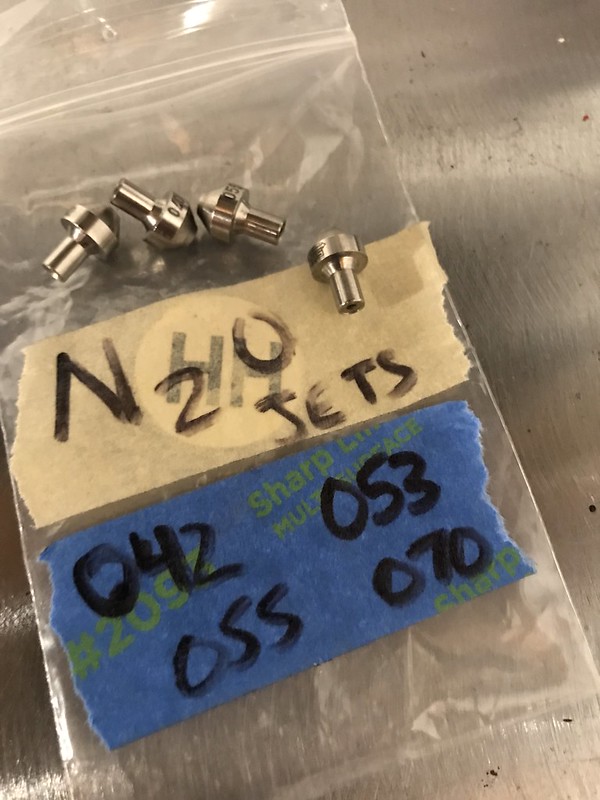

The olde TPI kit came with two set of jets 042 + 053 jets for the 100 shot, and 055 + 070 for the 150 shot . I am unsure if these jets will work for the cheater plate, because I read this link which tells me different jetting :

https://www.429-460.com/t25799-new-n...-cheater-plate

Nitrous Solenoid Driver (not a Relay) and wiring:

The NOS TPI kit came with a 30a/50a 12v relay which I am sure still works, but the Holley EFI system seems to require a high-current nitrous solenoid driver instead of a relay? interesting.

https://www.holley.com/products/fuel.../parts/554-111

Spark Plugs:

I have only ever used the Autolite 3924 spark plugs on this engine, as these were the engine builders recommendation. The next step colder would be an Autolite 3923 plug, so I think I will go with these. https://www.summitracing.com/parts/atl-3923

Chris Meyer of EFI systemsPro has a great article on all of this too:

https://www.efisystempro.com/efi-pro...-nitrous-oxide

OR

Anyways, the time has come for me to get this going. I am certainly no expert with nitrous, but I did run nitrous on the old 305 TPI engine for about 4 years. It made the 305 fun, but I basically just played around with it on the street, during autocross, and some drag racing. That kit was the NOS Powershot, which had 100 hp jets and 150 hp jets. Here is a link to the kit on Jegs: https://www.jegs.com/i/NOS/741/05151...QaAnd9EALw_wcB

So, I still have everything from this setup, and for my upcoming "version 1" of this upcoming nitrous system, I will be using most of the components. Instead of just drilling the engine with a 200 or 250 shot and having to buy new solenoids, I feel safer using the existing "smaller" solenoids for at least this fall 2021 season. I will be using the existing 10 pound bottle, its blow-down tube, the bottle pressure gauge and the main -4an fed line from the bottle. I also will be using my toggle switch setup that is mounted in the ashtray. I do not yet want a bottle heater, and I will never need a remote bottle opener since I can reach the bottle valve from my drivers seat. As mentioned, the NOS powershot solenoids are good for somewhere in the neighborhood of 150 hp (but I have read 175 can be done) so I will use those, along with the nitrous purge solenoid. I bought a NOS cheater wet-plate from a guy on thirdgen.org for $50 which was a heck of a deal. The wiring, and the relay will all be replaced with fresh new stuff, some colder spark plugs, and a new oxygen sensor with an O2 extender bung is also required. I am on the fence about using a fuel pressure safety switch, because I know it is a good idea, but mounting it in the tight area where I will have the fuel lines just might not work for me. I also do not plan to use a throttle mounted "window" activation switch, as I can control the nitrous both with my shifter mounted button AND also with the holley efi software.

I have been reading a lot about nitrous while using the holley sniper efi and I will get into some of that later. UNsure if I will be doing a progressive shot or not yet; maybe. This post is mostly for me to lay out the components and gameplan for everyone to look at, and then let me know their thoughts and technical opinions.

Bottle:

Use existing 10 pound NOS bottle with blow down tube.

Toggle switches:

Using the existing Nitrous Outlet ash-tray panel. I only plan to use the "master arming switch" and the "purge button". https://nitrousoutlet.com/i-30559860...tch-panel.html

Fuel Pressure safety switch:

undecided currently, but I will Probably get one

https://nitrousoutlet.com/i-30559952...-manifold.html

Oxygen sensor:

The nitrous guys that run the holley efi assure me that I will need a better O2 sensor as well as a special extender. (will add link later)

Lines/Plumbing:

I had used the braided -3an lines that came with the TPI kit on the TPI and they were good. They are way too long for my new setup. Instead of shortening them, I think i want to go with a hardline from the solenoids to the plate. Will do the -an flex lines to connect the fuel system to the solenoid, and to connect the nitrous bottle to the purge solenoid. But everything else I want to do with hardline.

- I am going to have to find a spot I am happy with to mount the solenoids in a spot that not only is visually appealing, but also serviceable and allows me to change jets easily. Therefore, instead of fighting with stainless steel lines at first, I might try to use some of my 3/16" (which is -3an) copper-nickel lines that remains from when I built my brake lines throughout the car. I have emailed Nitrous Express AND Nitrous Solutions who both told me that copper-nickle line is absolutely fine to use for hardline on a nitrous/fuel system. It will be much easier to bend, flare, and work with. However, they will not be shiny silver. If I can get the lines the way I want, maybe later I can re-create them with stainless. I will need to buy the proper fittings, tube nuts, and adapters. I also will need to buy a cheap-o 37degree flare tool, but I do have a tube bender already.

- Fuel line fittings will be needed too to T-off of the existing -8 fuel feed line. I will also re-install my Aeromotive fuel pressure gauge, and probably that fuel pressure safety switch, so it will be a cluttered area of fuel fittings and adapters.

Solenoid Locations/brackets:

This one is tricky, and right now I have about 3 possible options, but feel free to add in your suggestions. Number 1 priority is that the solenoids have to be mounted in a way that are visually appealing to me. I don't want to just have all sorts of brackets in random places with solenoids and lines hanging all over the top of the engine. No way. There are not too many choices that appeal to me, and maybe I could make my own later, but for now, I might use something like these and "drop-mount" them off the carb-mount studs. https://www.holley.com/products/nitr...parts/16523NOS Initially i wanted the solenoids all in that "valley" between the sniper and the thermostat housing. IT will get real tricky to make all the plumbing work that way, so I don't think its a realistic option. Also, the purge solenoid should be very close to the nitrous solenoid, so keep that in mind.

- Nitrous plate:

NOS cheater plate which i got for $50. It is capable of flowing up to a 250 hp wet shot, which is all I ever plan to put to this engine. link: https://www.jegs.com/i/NOS/741/12500...AaAkwmEALw_wcB I will buy some spare 4150 carb gaskets too for fresh gaskets during the install.

Jets:

The olde TPI kit came with two set of jets 042 + 053 jets for the 100 shot, and 055 + 070 for the 150 shot . I am unsure if these jets will work for the cheater plate, because I read this link which tells me different jetting :

https://www.429-460.com/t25799-new-n...-cheater-plate

Nitrous Solenoid Driver (not a Relay) and wiring:

The NOS TPI kit came with a 30a/50a 12v relay which I am sure still works, but the Holley EFI system seems to require a high-current nitrous solenoid driver instead of a relay? interesting.

https://www.holley.com/products/fuel.../parts/554-111

Spark Plugs:

I have only ever used the Autolite 3924 spark plugs on this engine, as these were the engine builders recommendation. The next step colder would be an Autolite 3923 plug, so I think I will go with these. https://www.summitracing.com/parts/atl-3923

Chris Meyer of EFI systemsPro has a great article on all of this too:

https://www.efisystempro.com/efi-pro...-nitrous-oxide

OR

The following users liked this post:

DynoDave43 (08-27-2021)

#2

Supreme Member

Re: Single-stage Nitrous for the 406 with Holley EFI

Very cool thread, I look forward to your updates!

#3

COTM Editor

iTrader: (22)

Join Date: Mar 2001

Posts: 9,932

Likes: 0

Received 1,861 Likes

on

1,275 Posts

Car: '89 Firebird

Engine: 7.0L

Transmission: T56

Re: Single-stage Nitrous for the 406 with Holley EFI

Seems like it's pretty much a standalone nitrous system. Holley Sniper EFI can't do controls and safety interlocks for you?

#4

Supreme Member

Thread Starter

iTrader: (25)

Join Date: Sep 2005

Location: NJ

Posts: 1,816

Received 280 Likes

on

218 Posts

Car: 1987 IROC-Z

Engine: 406 on N20 w/ EFI

Transmission: P.B. 700R4

Axle/Gears: 12 bolt w/ 3.91

Re: Single-stage Nitrous for the 406 with Holley EFI

Do ya mean progressive ramping the stage in? Or enabling it and disabling it under certainly throttle positions and rpms? It so, yes it can, and that’s why I won’t need a micro switch on the throttle like the old school method. In that link I posted at the very end of my first post, Chris Meyer briefly goes through these basic features of the Holley software and shows some screenshots of the software on there too. Or did you mean something different that I am

overlooking?

overlooking?

#5

Re: Single-stage Nitrous for the 406 with Holley EFI

Does the Sniper have a TPS?

I'd recommend using NGK plugs

I use -7 for street.

And -9 for 150 shots, although you may use -8

https://www.summitracing.com/parts/ngk-4554

Non projected plug

I'd recommend using NGK plugs

I use -7 for street.

And -9 for 150 shots, although you may use -8

https://www.summitracing.com/parts/ngk-4554

Non projected plug

The following users liked this post:

RoadRace (08-17-2023)

#6

Re: Single-stage Nitrous for the 406 with Holley EFI

main items of concern that pop in my head....

1. you need dead nuts pressure monitoring for nitrous pressure

2. you need dead nuts pressure monitoring for fuel pressure, to be set while it is flowing through a jet

3. you can run carb fuel pressure or efi pressure, and you would change jet sizes depending on which you are using. much more info out there for jetting a cheater plate on carb pressure.

4. you can use standard relays to operate your solenoids, but if using a progressive you would use that instead.

5. you will need a bottle heating setup to get the bottle to 900psi and be able to keep it there.

6. you need a way to pull timing when you arm the nitrous or when the nitrous is actually spraying.

7. i would see about doing a standalone fuel cell with a pump inside. you can then set it up for carb pressure and take the load off of your in tank fuel pump running the engine. also, you can put higher octane fuel in there.

8. use crimped hoses only for nitrous, not the ones you make yourself. i had one blow apart in my face once.

1. you need dead nuts pressure monitoring for nitrous pressure

2. you need dead nuts pressure monitoring for fuel pressure, to be set while it is flowing through a jet

3. you can run carb fuel pressure or efi pressure, and you would change jet sizes depending on which you are using. much more info out there for jetting a cheater plate on carb pressure.

4. you can use standard relays to operate your solenoids, but if using a progressive you would use that instead.

5. you will need a bottle heating setup to get the bottle to 900psi and be able to keep it there.

6. you need a way to pull timing when you arm the nitrous or when the nitrous is actually spraying.

7. i would see about doing a standalone fuel cell with a pump inside. you can then set it up for carb pressure and take the load off of your in tank fuel pump running the engine. also, you can put higher octane fuel in there.

8. use crimped hoses only for nitrous, not the ones you make yourself. i had one blow apart in my face once.

#7

Supreme Member

Thread Starter

iTrader: (25)

Join Date: Sep 2005

Location: NJ

Posts: 1,816

Received 280 Likes

on

218 Posts

Car: 1987 IROC-Z

Engine: 406 on N20 w/ EFI

Transmission: P.B. 700R4

Axle/Gears: 12 bolt w/ 3.91

Re: Single-stage Nitrous for the 406 with Holley EFI

Thanks guys. I appreciate the tech advice.

LB9GTA;

Yes, the sniper has a TPS sensor and a lot of the sniper tables are based off the TPS so it is always "in-play". For nitrous, there are software/programmable options to allow the nittous to come on (or turn off) at set TPS percentages. So if I were to pedal the car, and drop below the set percentage, the nitrous would turn off. You can add in a delay also, so if I got back on the throttle I could program in a small delay despite if I was at 100% wot or not. Is this what you were gettin at or ?

-Thanks for the plug suggestion, it might be something I change on over to after seeing what these Autolite 3923 plugs do. I picked the 3923 at the advice of the Engine builder who builds a lot of high horsepower small/big block chevys, many of them see nitrous often. he said for sure a 3923 would suit me right, but I am not opposed to trying those NGK plugs as well. thanks!

Diggler:

I have had ideas about doing a small fuel tank under the hood just for nitrous. While it would be cool, its not something I can afford right now, and every mod I do keeps making the car heavier and heavier...its surprisingly heavy. I also just really don't know if I like the look of the tanks under the hood. I still take this car to car shows and I try to keep the engine bay extremely simply, clutter-free and clean. having hoses and lines all over the place is very undesirable, so I would really have to plan out a tank and hose system that is discrete and clean.

1. as for the nitrous pressure, thats going to be a challenge for me going forward. I do want to do a bottle heater, but I would only leave the heater strapped on the bottle for racing events. They look ugly, and hte tank is very visible in the car. I do have a bottle pressure gauge on the bottle and i can read it from the drivers seat. I will have a purge solenoid setup, but since I only currently have one nitrous bottle, I will probably only get about 4 full passes with a nitrous bottle per race day. A secondary bottle would be great, but they are about $300 and I would have to put that on the "buy later" list

2. The fuel pressure of the system is currently regulated by the holley sniper with a regulator that is on the return port of the sniper. It is pre set to 58-60 psi and they are not adjustable. I have a racetronix 340 lph pump, with the upgraded heavier gauge wiring. I run a -8an feed line and a -6 return line to the in tank racetronix pump. I have an aeromotive in-line fuel pressure gauge on the fuel line, but I don't know how I would actually test the fuel pressure that is flowing through a fuel jet?? I spoke with racetronix about my setup last year and he said I should be capable of safely fueling the engine with an additional 200 shot and not starving anything for fuel. We did some quick math on this, but I don't have it written down.

3. see above....also I ran into the same info you mentioned about the jetting for a cheater plate using a carb psi vs fuel injector psi. I actually called Holley/NOS today on my lunch break about this exact question. My tpi system was at 43 psi fuel pressure and used a 070 nitrous jet with a 53 fuel jet (for a 150 shot). The tech guy on the phone said that now since I will have a 60 psi fuel system, I should still use the 070 nitrous jet but to lower the fuel jet to about an 040 and then watch my afr on datalogs. Since I will have more fuel pressure I should downsize the jet. He told me that LS style engines use around 60 psi, so I should try to search out a nitrous/fuel jetting for a LS because there is probably a jetting chart that would get me in the ballpark. he did say that an 070 and 040 combination would be close enough to start. Thoughts?

edit: found this onlinr jet calculator tool: http://www.robietherobot.com/nitrousjetcalculator.htm

and this chart for 55 psi efi plates: https://www.nitrousexpress.com/image...atejetting.pdf

4. While I wouldn't mind having a non-progressive setup, I feel that it is smarter to have the ability to make it progressive, therefore I went ahead an bought the solenoid driver so that I do have the option to ramp in a progressive stage. Seems to make sense long-term.

5. yup. I agree. see above. Would also like a spare bottle too.

6. the holley sniper software is capable of doing that. On my old TPI setup, I had used a MSD digital 6-Plus box to pull 4 deg timing on my 100 shot. The box worked great, but now I use the sniper and the hyperspark ignition. Both will absolutely pull timing when the nitrous is spraying. Spoke with my engine builder today also and he told me that he usually pulls 2 deg for a 100 shot (as opposed to what i used to do... 4 deg for a 100 shot). He said that I could pull 3 degrees for my 150 shot, or if I felt more comfortable, i could pull 4 deg for 150. He also said to target an AFR of 12.5:1 when the nitrous is flowing. Check datalogs and adjust accordingly...also the sniper can learn not only N/A but it can learn on nitrous and build its own nitrous learn table too.

7. yup, see above at the top

8. I do have some crimped hoses, they came with the tpi kit and are in the photo above. They are ridiculously long for the very short distance I plan to need. But, Maybe I will re-use those if I can't get the hardlines to work. I am aware of how to assemble ptfe lines, I did so for my entire fuel system from start to finish. So it is an option. I just still do not yet know how I am going to locate the solenoids and the cheater plate. Once I figure that out, I can start to get creative with the line routing. You had what type of line blow up? steel? yikes. not good. I do think my copper-nickle will work, even if just for a few months and I can redo the lines with braided ptfe or stainless over the winter. This first nitrous layout is probably "phase 1" and will result in some changes over the winter.

So,m last night I ordered most of what I will need. (I did not order any fittings, tube nuts, etc since I still do not yet know the solenoid layout) (also did not order more jets, as I gotta find a chart to see what ones I might need for a 100 shot, 150 shot, and a 175 shot)

- 4 solenoid drop-brackets NOS 16523NOS

- high pressure adjustable Fuel pressure safety switch -6an Nitrous Outlet 00-60001-6

- NTK oxygen sensor for holley sniper NTK554-100

- Innovate Motorsports oxygen sensor extender HBX-1 3729

- Holley High Current Nitrous Solenoid Driver 554-111

- 37 degree -an flaring tool SUM-900311

- 8 Autolite 3923 Copper spark plugs

- 3 carburetor gaskets

Stuff was ordered from Summit racing, and hopefully will arrive as expected on Friday, so I might make some progress this weekend. maybe

During my chat with Holley/NOS today, I asked for clarification about the Powershot solenoids that came in my TPI kit (which i will be reusing). I was told that my nitrous solenoid can flow up to a 175 shot and my fuel solenoid is capable of a 200 shot. This is enough for me for the rest of 2021, so I Just gotta find jets for these.

LB9GTA;

Yes, the sniper has a TPS sensor and a lot of the sniper tables are based off the TPS so it is always "in-play". For nitrous, there are software/programmable options to allow the nittous to come on (or turn off) at set TPS percentages. So if I were to pedal the car, and drop below the set percentage, the nitrous would turn off. You can add in a delay also, so if I got back on the throttle I could program in a small delay despite if I was at 100% wot or not. Is this what you were gettin at or ?

-Thanks for the plug suggestion, it might be something I change on over to after seeing what these Autolite 3923 plugs do. I picked the 3923 at the advice of the Engine builder who builds a lot of high horsepower small/big block chevys, many of them see nitrous often. he said for sure a 3923 would suit me right, but I am not opposed to trying those NGK plugs as well. thanks!

Diggler:

I have had ideas about doing a small fuel tank under the hood just for nitrous. While it would be cool, its not something I can afford right now, and every mod I do keeps making the car heavier and heavier...its surprisingly heavy. I also just really don't know if I like the look of the tanks under the hood. I still take this car to car shows and I try to keep the engine bay extremely simply, clutter-free and clean. having hoses and lines all over the place is very undesirable, so I would really have to plan out a tank and hose system that is discrete and clean.

1. as for the nitrous pressure, thats going to be a challenge for me going forward. I do want to do a bottle heater, but I would only leave the heater strapped on the bottle for racing events. They look ugly, and hte tank is very visible in the car. I do have a bottle pressure gauge on the bottle and i can read it from the drivers seat. I will have a purge solenoid setup, but since I only currently have one nitrous bottle, I will probably only get about 4 full passes with a nitrous bottle per race day. A secondary bottle would be great, but they are about $300 and I would have to put that on the "buy later" list

2. The fuel pressure of the system is currently regulated by the holley sniper with a regulator that is on the return port of the sniper. It is pre set to 58-60 psi and they are not adjustable. I have a racetronix 340 lph pump, with the upgraded heavier gauge wiring. I run a -8an feed line and a -6 return line to the in tank racetronix pump. I have an aeromotive in-line fuel pressure gauge on the fuel line, but I don't know how I would actually test the fuel pressure that is flowing through a fuel jet?? I spoke with racetronix about my setup last year and he said I should be capable of safely fueling the engine with an additional 200 shot and not starving anything for fuel. We did some quick math on this, but I don't have it written down.

3. see above....also I ran into the same info you mentioned about the jetting for a cheater plate using a carb psi vs fuel injector psi. I actually called Holley/NOS today on my lunch break about this exact question. My tpi system was at 43 psi fuel pressure and used a 070 nitrous jet with a 53 fuel jet (for a 150 shot). The tech guy on the phone said that now since I will have a 60 psi fuel system, I should still use the 070 nitrous jet but to lower the fuel jet to about an 040 and then watch my afr on datalogs. Since I will have more fuel pressure I should downsize the jet. He told me that LS style engines use around 60 psi, so I should try to search out a nitrous/fuel jetting for a LS because there is probably a jetting chart that would get me in the ballpark. he did say that an 070 and 040 combination would be close enough to start. Thoughts?

edit: found this onlinr jet calculator tool: http://www.robietherobot.com/nitrousjetcalculator.htm

and this chart for 55 psi efi plates: https://www.nitrousexpress.com/image...atejetting.pdf

4. While I wouldn't mind having a non-progressive setup, I feel that it is smarter to have the ability to make it progressive, therefore I went ahead an bought the solenoid driver so that I do have the option to ramp in a progressive stage. Seems to make sense long-term.

5. yup. I agree. see above. Would also like a spare bottle too.

6. the holley sniper software is capable of doing that. On my old TPI setup, I had used a MSD digital 6-Plus box to pull 4 deg timing on my 100 shot. The box worked great, but now I use the sniper and the hyperspark ignition. Both will absolutely pull timing when the nitrous is spraying. Spoke with my engine builder today also and he told me that he usually pulls 2 deg for a 100 shot (as opposed to what i used to do... 4 deg for a 100 shot). He said that I could pull 3 degrees for my 150 shot, or if I felt more comfortable, i could pull 4 deg for 150. He also said to target an AFR of 12.5:1 when the nitrous is flowing. Check datalogs and adjust accordingly...also the sniper can learn not only N/A but it can learn on nitrous and build its own nitrous learn table too.

7. yup, see above at the top

8. I do have some crimped hoses, they came with the tpi kit and are in the photo above. They are ridiculously long for the very short distance I plan to need. But, Maybe I will re-use those if I can't get the hardlines to work. I am aware of how to assemble ptfe lines, I did so for my entire fuel system from start to finish. So it is an option. I just still do not yet know how I am going to locate the solenoids and the cheater plate. Once I figure that out, I can start to get creative with the line routing. You had what type of line blow up? steel? yikes. not good. I do think my copper-nickle will work, even if just for a few months and I can redo the lines with braided ptfe or stainless over the winter. This first nitrous layout is probably "phase 1" and will result in some changes over the winter.

So,m last night I ordered most of what I will need. (I did not order any fittings, tube nuts, etc since I still do not yet know the solenoid layout) (also did not order more jets, as I gotta find a chart to see what ones I might need for a 100 shot, 150 shot, and a 175 shot)

- 4 solenoid drop-brackets NOS 16523NOS

- high pressure adjustable Fuel pressure safety switch -6an Nitrous Outlet 00-60001-6

- NTK oxygen sensor for holley sniper NTK554-100

- Innovate Motorsports oxygen sensor extender HBX-1 3729

- Holley High Current Nitrous Solenoid Driver 554-111

- 37 degree -an flaring tool SUM-900311

- 8 Autolite 3923 Copper spark plugs

- 3 carburetor gaskets

Stuff was ordered from Summit racing, and hopefully will arrive as expected on Friday, so I might make some progress this weekend. maybe

During my chat with Holley/NOS today, I asked for clarification about the Powershot solenoids that came in my TPI kit (which i will be reusing). I was told that my nitrous solenoid can flow up to a 175 shot and my fuel solenoid is capable of a 200 shot. This is enough for me for the rest of 2021, so I Just gotta find jets for these.

Last edited by IROCZman15; 08-25-2021 at 10:06 PM.

Trending Topics

#8

Re: Single-stage Nitrous for the 406 with Holley EFI

Please do not use the AF gauge for your tune!

Pull plugs, every time you make a pass, until you have a safe tune.

Fresh plugs, drive to the lanes and run it.

Stop after the race, pull over and pull the plugs. Check them.

Pull more timing than you need.

Easier to add timing later, than to not pull enough timing and blow your engine.

I'm talking from experience...

Pull plugs, every time you make a pass, until you have a safe tune.

Fresh plugs, drive to the lanes and run it.

Stop after the race, pull over and pull the plugs. Check them.

Pull more timing than you need.

Easier to add timing later, than to not pull enough timing and blow your engine.

I'm talking from experience...

The following users liked this post:

RoadRace (08-17-2023)

#9

Supreme Member

Thread Starter

iTrader: (25)

Join Date: Sep 2005

Location: NJ

Posts: 1,816

Received 280 Likes

on

218 Posts

Car: 1987 IROC-Z

Engine: 406 on N20 w/ EFI

Transmission: P.B. 700R4

Axle/Gears: 12 bolt w/ 3.91

Re: Single-stage Nitrous for the 406 with Holley EFI

I wasn't clear about what I meant by that. I didn't plan on just making a tune and simply only datalogging to make adjustments. I would use the datalogged AFR to make sure my tune is not WAYY off.

- I know plug reading is super important. I did a bit of that when i was spraying the 100 shot on the TPI engine for a few years. I will have to re-train my self on what to look for regarding the plugs. I know that the "color change" mark on the grounding strap should be right near the bend of the strap. if it is too far either way, timing adjustment needs to be made. Also, the fuel ring on the porcelain. What else? I knew not to get iridium or platinum plugs too, thats why the copper Autolites were purchased.

-However, there is no chance that i can shut off the engine after I go through the traps and then coast all the way back to my pit spot. At island dragway you have to go around a tight 180 degree turn, over a birdge, around another turn, and to the timing tower to get your slip. The bumpy curvy road is only 8 feet wide, no room for hanging out and blocking other cars on the return road. The best option I have is to make the 1/4 mile pass, slow down in the shutdown, coast around the turns and over the bridge, to the timing tower, and then coast to my pit spot...where I would then turn off the engine and check the plugs. Basically this is what everyone seems to do, even the multi-stage nitrous guys are not getting towed back by atv's at this track. I have never once seen anyone checking plugs in the grassy area along the return road.. its just not how Island Dragway operates.

I FULLY AGREE with you about pulling more timing out and being safe about this, and then adding timing back later. I am not planning on going for the glory shot on my first outing. I will keep it safe, so probably pulling out 4 or 5 degrees for the 100 shot.

Some of the boxes arrive tomorrow, so I hope to make some progress on the install this weekend.

everyone, feel free to comment, question, or add info here. I very much appreciate all advice and criticism. I simply just want to make sure I do everything as best as possible.

- I know plug reading is super important. I did a bit of that when i was spraying the 100 shot on the TPI engine for a few years. I will have to re-train my self on what to look for regarding the plugs. I know that the "color change" mark on the grounding strap should be right near the bend of the strap. if it is too far either way, timing adjustment needs to be made. Also, the fuel ring on the porcelain. What else? I knew not to get iridium or platinum plugs too, thats why the copper Autolites were purchased.

-However, there is no chance that i can shut off the engine after I go through the traps and then coast all the way back to my pit spot. At island dragway you have to go around a tight 180 degree turn, over a birdge, around another turn, and to the timing tower to get your slip. The bumpy curvy road is only 8 feet wide, no room for hanging out and blocking other cars on the return road. The best option I have is to make the 1/4 mile pass, slow down in the shutdown, coast around the turns and over the bridge, to the timing tower, and then coast to my pit spot...where I would then turn off the engine and check the plugs. Basically this is what everyone seems to do, even the multi-stage nitrous guys are not getting towed back by atv's at this track. I have never once seen anyone checking plugs in the grassy area along the return road.. its just not how Island Dragway operates.

I FULLY AGREE with you about pulling more timing out and being safe about this, and then adding timing back later. I am not planning on going for the glory shot on my first outing. I will keep it safe, so probably pulling out 4 or 5 degrees for the 100 shot.

Some of the boxes arrive tomorrow, so I hope to make some progress on the install this weekend.

everyone, feel free to comment, question, or add info here. I very much appreciate all advice and criticism. I simply just want to make sure I do everything as best as possible.

#10

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,034

Received 517 Likes

on

431 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: Single-stage Nitrous for the 406 with Holley EFI

Check this out:

The following users liked this post:

RoadRace (08-17-2023)

#11

Re: Single-stage Nitrous for the 406 with Holley EFI

These guys have more nitrous experience than me but on my 383 i ran several bottles thru it at 150 shot levels and i basically used track mph and air fuel for tuning. Stock recommended jetting in my hitman kit was way rich. I jetted the fuel down a lot and picked up 4 mph. I think i targeted 11.8-12.0 afr. I pulled 3-4 deg i think. I think i had 7 heat range ngk plugs but i did have air fuel distribution issues as i found one plug did end up eating a ground strap lol. But it ran hard. Nitrous is fun but adds up lol go thru gas quickly i found

#12

Re: Single-stage Nitrous for the 406 with Holley EFI

i ran a 1 gallon cell sitting in the battery tray location for my standalone. i had a walbro 180 or something like that in there and it had no issues delivering what i needed. ran pump in tank and race gas in cell for awhile.

One of the best reasons for running carb pressure on that cheater plate is there is a huge amount of r&d on it available on the net. if you look at the jetting chart that came with that plate, it is actually way rich. in fact, you could pretty much swap the fuel and nitrous jet recommendations and it would come out about right. so to save yourself several dozen spark plugs and bottles of nitrous trying to get it dialed in, you can simply put it to where some of the guys on yellowbullet.com recommend. (fuel pressure and jet sizes) there was tons of info on that site at one time.

for timing, i was always extra extra safe. i think i was pulling 6 deg. on a 150-175 shot. base timing was 32 for my combo.

you will want to read plugs, but i would recommend to save some time and money go ahead and find your 2 leanest/hottest holes and just check those after a pass. that way you wont have to change out all 8 plugs every time you want to get a read on the tune.

stainless braided line blew up in my face. i was a complete moron and didnt even realize there was a different hose type needed for that amount of pressure, so i made my own. it worked for awhile but eventually came apart at the fitting. there wont be that much pressure after the solenoid, so you could possibly get away with making those. hard lines should be fine.

One of the best reasons for running carb pressure on that cheater plate is there is a huge amount of r&d on it available on the net. if you look at the jetting chart that came with that plate, it is actually way rich. in fact, you could pretty much swap the fuel and nitrous jet recommendations and it would come out about right. so to save yourself several dozen spark plugs and bottles of nitrous trying to get it dialed in, you can simply put it to where some of the guys on yellowbullet.com recommend. (fuel pressure and jet sizes) there was tons of info on that site at one time.

for timing, i was always extra extra safe. i think i was pulling 6 deg. on a 150-175 shot. base timing was 32 for my combo.

you will want to read plugs, but i would recommend to save some time and money go ahead and find your 2 leanest/hottest holes and just check those after a pass. that way you wont have to change out all 8 plugs every time you want to get a read on the tune.

stainless braided line blew up in my face. i was a complete moron and didnt even realize there was a different hose type needed for that amount of pressure, so i made my own. it worked for awhile but eventually came apart at the fitting. there wont be that much pressure after the solenoid, so you could possibly get away with making those. hard lines should be fine.

#13

Supreme Member

iTrader: (11)

Join Date: Aug 2013

Location: MICHIGAN

Posts: 4,643

Received 754 Likes

on

580 Posts

Car: 1988 Trans Am

Engine: L03

Transmission: 700R4

Axle/Gears: 10 Bolt 2.73 Open

Re: Single-stage Nitrous for the 406 with Holley EFI

- NTK oxygen sensor for holley sniper NTK554-100

- Innovate Motorsports oxygen sensor extender HBX-1 3729

- 8 Autolite 3923 Copper spark plugs

Stuff was ordered from Summit racing, and hopefully will arrive as expected on Friday, so I might make some progress this weekend. maybe

The new oxygen sensor....why? Was the sensor that came with the Sniper system not a wide band?

Oxygen sensor extender. This moves the sensor further out of the hole / pipe to keep it cooler? Do that also not make it less accurate, or slower to respond, not being fully in the exhaust stream?

Copper plugs. You said you knew better than to run iridium or platinum. But I don't!

Why are they a no-no?

Why are they a no-no?

#14

Supreme Member

Thread Starter

iTrader: (25)

Join Date: Sep 2005

Location: NJ

Posts: 1,816

Received 280 Likes

on

218 Posts

Car: 1987 IROC-Z

Engine: 406 on N20 w/ EFI

Transmission: P.B. 700R4

Axle/Gears: 12 bolt w/ 3.91

Re: Single-stage Nitrous for the 406 with Holley EFI

No Emissions: wow, that is incredible! I am definitely going to try that out. Super cool

Orr : I was hoping that you would see this thread and chime in! I remembered that before your turbo 555 monster you had a nitroused 383, so I am glad you found my thread. Good to know that the 150 shot is going to be strong enough for me to feel the power, yet small enough where I can focus on reading plugs, afr, datalogging and keep the engine safe and happy. I think the 12.0 afr is a good spot for me to start at. I still have to figure out a proper array of jets to buy to give me enough adjustable options, but without spending huge money on an entire suit-case of nitrous jets! Also, See my write-up below for what I plan to do regarding bottles and fillups.

Diggler. I do agree. That cheater plate was on artic-whites carburetor engine and I know that the cheater plate was designed for the carb setup and not an efi tbi setup with higher pressure. While it would be way cool to have a stand alone fuel cell and pump under the hood, for this current season/setup I am not able to afford it and not able to swallow the concept of adding more weight and clunky stuff under the hood. The cleanest system I have seen is the stand alone Fitech fuel tank/pump, and it is still too expensive and does not fit the design/look of my engine bay layout. I think I am stuck jetting the cheater plate off of the 60 psi range of my current fuel system.

- that is a great idea about figuring out which two cylinders run the leanest out of all 8! Typically when i checked plugs I would check the ones that were the easiest/quickest for me to check (like 1, 3, 2 and 8. But I see the logic in your statement, and i can spend some time figuring out what cylinders are the leanest of them all and then use those as a bottom-line to tune upwards from. Awesome! Base timing for this engine we have found that 34.5 degrees at full advance. So if I start out with a 50 shot, ill pull 2 deg. Read plugs, and then go from there on upwards...safely. I will probably post photos on here for group discussion.

-ah gotcha, a briaded line blew up. Now I understand. yes there are different versions of braided hoses. from my experience the PTFE braided are best (currently). Today I was chatting with a friend who used to work on slammed trucks, imports, and low riders. he used to bend up all sorts of stainless lines for those cars and showed me some photos of the tricked out plumbing he had done. He said he would be glad to help out and has some high dollar flare and bending tools. We discussed that it might be smart for me to put in the effort and build my "version 1" set of lines out of the copper-nickle with all the fittings I need and get the system up and running. Then, when he has time to come over, we can take my copper-nickle lines off, and duplicate them out of stainless steel (and adjust the bends as needed) and then install them after a good polishing. That seems like a good idea. Thoughts?

Dynodave, glad to have ya here too, feel free to ask away and hopefully these experienced guys can answer also. As for your current questions, your timing about the oxygen sensor is perfect. I wrote up a description in the "sidenote" just below this one. Long story short, the current oxygen sensor (and the new extender) will be just fine. No need for the (expensive) NTK sensor, that is for other Holley EFI systems, not my sniper setup. As for the extender, everyone on the holley forums is very vocal that the HBX-1 extender is a must have. Somehow, scientifically, it does not skew the readings and the sensor performs exactly as it should. Otherwise I couldn't see it being recommended by so many people for so many years. It is super import and for any type of forced induction. It also helps with cars that produce a lot of water in teh exhaust and it prevents the o2 sensor from being thermally shocked by water droplets. There is some really good tech info here in the post by Danny Cabral at 5:08pm on 1/20/13. https://forums.holley.com/showthread...4322#post14322

-regarding the platinum/iridium plugs, I think most nitrous companies say to use copper. Platinum plugs tend to retain heat longer and therefore the stored heat is more likely to cause pre-ignition/detonation. Also, Platinum tipped ones can occasionally have the tips falloff and then your plug gap is different/bigger. Also, the cost per-plug is much higher and if I am going to be cutting open lots of spark plugs while dialing in the jetting, the copper plugs are more wallet friendly. I am sure some of the other nitrous guys on here could also clarify more on this topic too..

Stopped by Bruce's speed shop today to get my 10 pound bottle filled. I had emptied it down to zero so it was dead empty. Bruce now charges for nitrous by the pound, which is good, because I will just need to get the bottle topped off from time-to-time and not need a full fill. I am considering a second bottle to keep as a spare full bottle, as this will cut my trips to his shop in half. new bottles are expensive thought at $300 a piece! yikes

UPS brought my summit racing order today.

-sidenote: I will be returning the $290 NTK wideband oxygen sensor. I had done a bunch of research on the Holley EFi websites and the NTK sensor is highly recommended for nitrous(forced induction) setups. Yet, just today I spoke with one of the top tech guys via email who told me that the NTK sensor is compatible with all other holley EFI systems, however it is NOT compatible with the holley sniper system. So, I verified, that my best course of action is to use the Innovate HBX-1 extender along with my current oem holley bosch sensor. It will be good to go. So, I might take the money from the returned sensor and either buy a second nitrous bottle, OR buy a removable bottle heater. Those bottle mounts with the bottle heater built in are cool too, but way too expensive for me. There seems to be a lot of bottle heater options, so I will have to do some research on that topic.

Hope to make some progress this weekend with mounting and wiring, that way i can figure out what fittings I need to order. Also, still waiting on the fuel pressure safety switch to arrive, delivery scheduled for next Thursday.

Orr : I was hoping that you would see this thread and chime in! I remembered that before your turbo 555 monster you had a nitroused 383, so I am glad you found my thread. Good to know that the 150 shot is going to be strong enough for me to feel the power, yet small enough where I can focus on reading plugs, afr, datalogging and keep the engine safe and happy. I think the 12.0 afr is a good spot for me to start at. I still have to figure out a proper array of jets to buy to give me enough adjustable options, but without spending huge money on an entire suit-case of nitrous jets! Also, See my write-up below for what I plan to do regarding bottles and fillups.

Diggler. I do agree. That cheater plate was on artic-whites carburetor engine and I know that the cheater plate was designed for the carb setup and not an efi tbi setup with higher pressure. While it would be way cool to have a stand alone fuel cell and pump under the hood, for this current season/setup I am not able to afford it and not able to swallow the concept of adding more weight and clunky stuff under the hood. The cleanest system I have seen is the stand alone Fitech fuel tank/pump, and it is still too expensive and does not fit the design/look of my engine bay layout. I think I am stuck jetting the cheater plate off of the 60 psi range of my current fuel system.

- that is a great idea about figuring out which two cylinders run the leanest out of all 8! Typically when i checked plugs I would check the ones that were the easiest/quickest for me to check (like 1, 3, 2 and 8. But I see the logic in your statement, and i can spend some time figuring out what cylinders are the leanest of them all and then use those as a bottom-line to tune upwards from. Awesome! Base timing for this engine we have found that 34.5 degrees at full advance. So if I start out with a 50 shot, ill pull 2 deg. Read plugs, and then go from there on upwards...safely. I will probably post photos on here for group discussion.

-ah gotcha, a briaded line blew up. Now I understand. yes there are different versions of braided hoses. from my experience the PTFE braided are best (currently). Today I was chatting with a friend who used to work on slammed trucks, imports, and low riders. he used to bend up all sorts of stainless lines for those cars and showed me some photos of the tricked out plumbing he had done. He said he would be glad to help out and has some high dollar flare and bending tools. We discussed that it might be smart for me to put in the effort and build my "version 1" set of lines out of the copper-nickle with all the fittings I need and get the system up and running. Then, when he has time to come over, we can take my copper-nickle lines off, and duplicate them out of stainless steel (and adjust the bends as needed) and then install them after a good polishing. That seems like a good idea. Thoughts?

Dynodave, glad to have ya here too, feel free to ask away and hopefully these experienced guys can answer also. As for your current questions, your timing about the oxygen sensor is perfect. I wrote up a description in the "sidenote" just below this one. Long story short, the current oxygen sensor (and the new extender) will be just fine. No need for the (expensive) NTK sensor, that is for other Holley EFI systems, not my sniper setup. As for the extender, everyone on the holley forums is very vocal that the HBX-1 extender is a must have. Somehow, scientifically, it does not skew the readings and the sensor performs exactly as it should. Otherwise I couldn't see it being recommended by so many people for so many years. It is super import and for any type of forced induction. It also helps with cars that produce a lot of water in teh exhaust and it prevents the o2 sensor from being thermally shocked by water droplets. There is some really good tech info here in the post by Danny Cabral at 5:08pm on 1/20/13. https://forums.holley.com/showthread...4322#post14322

-regarding the platinum/iridium plugs, I think most nitrous companies say to use copper. Platinum plugs tend to retain heat longer and therefore the stored heat is more likely to cause pre-ignition/detonation. Also, Platinum tipped ones can occasionally have the tips falloff and then your plug gap is different/bigger. Also, the cost per-plug is much higher and if I am going to be cutting open lots of spark plugs while dialing in the jetting, the copper plugs are more wallet friendly. I am sure some of the other nitrous guys on here could also clarify more on this topic too..

Stopped by Bruce's speed shop today to get my 10 pound bottle filled. I had emptied it down to zero so it was dead empty. Bruce now charges for nitrous by the pound, which is good, because I will just need to get the bottle topped off from time-to-time and not need a full fill. I am considering a second bottle to keep as a spare full bottle, as this will cut my trips to his shop in half. new bottles are expensive thought at $300 a piece! yikes

UPS brought my summit racing order today.

-sidenote: I will be returning the $290 NTK wideband oxygen sensor. I had done a bunch of research on the Holley EFi websites and the NTK sensor is highly recommended for nitrous(forced induction) setups. Yet, just today I spoke with one of the top tech guys via email who told me that the NTK sensor is compatible with all other holley EFI systems, however it is NOT compatible with the holley sniper system. So, I verified, that my best course of action is to use the Innovate HBX-1 extender along with my current oem holley bosch sensor. It will be good to go. So, I might take the money from the returned sensor and either buy a second nitrous bottle, OR buy a removable bottle heater. Those bottle mounts with the bottle heater built in are cool too, but way too expensive for me. There seems to be a lot of bottle heater options, so I will have to do some research on that topic.

Hope to make some progress this weekend with mounting and wiring, that way i can figure out what fittings I need to order. Also, still waiting on the fuel pressure safety switch to arrive, delivery scheduled for next Thursday.

The following users liked this post:

DynoDave43 (08-28-2021)

#15

Supreme Member

Thread Starter

iTrader: (25)

Join Date: Sep 2005

Location: NJ

Posts: 1,816

Received 280 Likes

on

218 Posts

Car: 1987 IROC-Z

Engine: 406 on N20 w/ EFI

Transmission: P.B. 700R4

Axle/Gears: 12 bolt w/ 3.91

Re: Single-stage Nitrous for the 406 with Holley EFI

Installed the HBX-1 Oxygen sensor extender today. Made sure to line up the indicator dot with the incoming stream of airflow from the engine.

Painted the side surfaces of the cheater plate with an aluminum colored spray paint and high temp clear. Sanded down the mounting surfaces to be smooth too. new gaskets on each side.

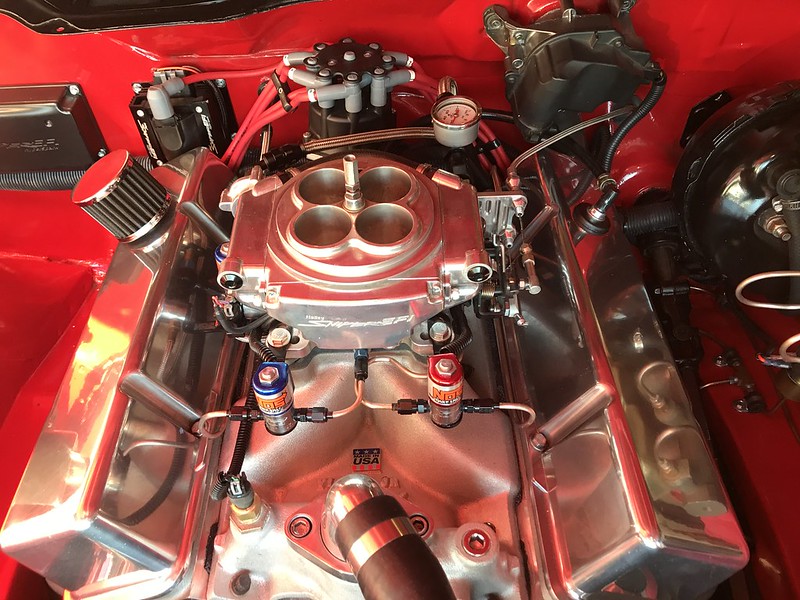

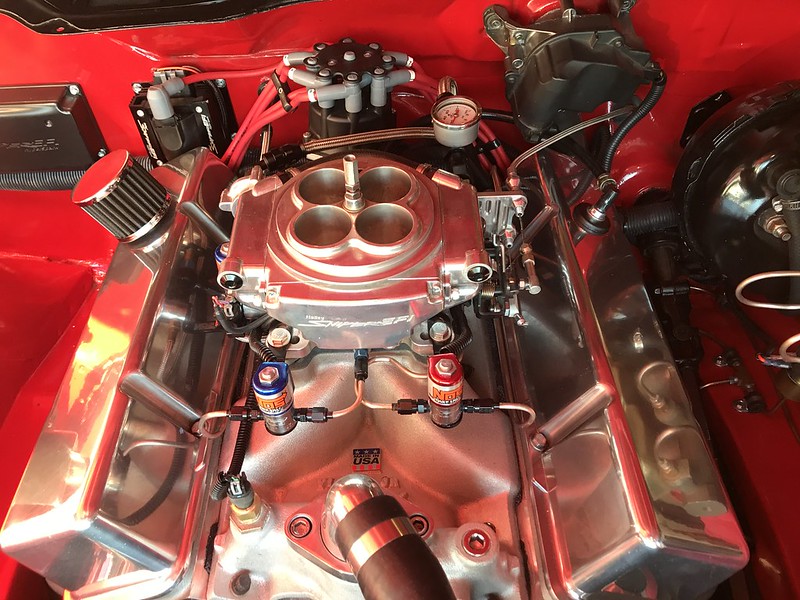

Spent some time trying to figure out the best functional/aesthetic/logical places to mount the 3 solenoids. (Fuel, nitrous, and nitrous purge solenoids). Gotta make sure that the in/out ports will be in the right direction, as well as trying to keep the purge solenoid close enough to the nitrous flow solenoid.

Ignore the placement of the blue t-fittings in this, it was not int eh correct spot but I was checking stuff clearance related.

I am going to have to come up with a list of proper fittings and adapters to order, but I think i might have to wait for the fuel safety switch to arrive. maybe. Unsure if I will do all black fittings or blue nitrous fittings and red fuel fittings.

Painted the side surfaces of the cheater plate with an aluminum colored spray paint and high temp clear. Sanded down the mounting surfaces to be smooth too. new gaskets on each side.

Spent some time trying to figure out the best functional/aesthetic/logical places to mount the 3 solenoids. (Fuel, nitrous, and nitrous purge solenoids). Gotta make sure that the in/out ports will be in the right direction, as well as trying to keep the purge solenoid close enough to the nitrous flow solenoid.

Ignore the placement of the blue t-fittings in this, it was not int eh correct spot but I was checking stuff clearance related.

I am going to have to come up with a list of proper fittings and adapters to order, but I think i might have to wait for the fuel safety switch to arrive. maybe. Unsure if I will do all black fittings or blue nitrous fittings and red fuel fittings.

#16

Re: Single-stage Nitrous for the 406 with Holley EFI

IF your want to pick up a 1 gal fuel tank and reg for the NOS set up. I have it all new in boxes..will make ya a deal. to save ya money. and make room for me at the same time.. will get some picks up in a few.. top name brand parts..

will get some picks up in a few.. top name brand parts..

will get some picks up in a few.. top name brand parts..

will get some picks up in a few.. top name brand parts..

#17

Supreme Member

Thread Starter

iTrader: (25)

Join Date: Sep 2005

Location: NJ

Posts: 1,816

Received 280 Likes

on

218 Posts

Car: 1987 IROC-Z

Engine: 406 on N20 w/ EFI

Transmission: P.B. 700R4

Axle/Gears: 12 bolt w/ 3.91

Re: Single-stage Nitrous for the 406 with Holley EFI

Articwhite: possibly, but not for this short remaining 3-month time period I have left before winter-time. I just want this system up and running so that as soon as the car is ready, i can get to the dragstrip and HOPEFULLY get a 10 second timeslip. During the fall, if I find that I would benefit from a fuel cell system, I might take you up on that. But I gotta keep my budget in mind and pick and choose my entire exhaust system renovation.

Got most of the engine bay wiring done today. Wired up the nitrous driver solenoid, the power and ground wires to the nitrous/fuel solenoids, and the purge solenoid too. Gotta finish covering everything in protective split-loom, and then run some wires into the cabin to my buttons.

Gotta place the order for the -an fittings too, maybe later tonight. Gotta also change the spark plugs and then start to get into the holley software to build a base tune. Oh, and also, I gotta order some nitrous jets. have yet to do the math on what jets I'll need for a 100, 150, and 175 shot, with a fuel pressure at 60psi.

Got most of the engine bay wiring done today. Wired up the nitrous driver solenoid, the power and ground wires to the nitrous/fuel solenoids, and the purge solenoid too. Gotta finish covering everything in protective split-loom, and then run some wires into the cabin to my buttons.

Gotta place the order for the -an fittings too, maybe later tonight. Gotta also change the spark plugs and then start to get into the holley software to build a base tune. Oh, and also, I gotta order some nitrous jets. have yet to do the math on what jets I'll need for a 100, 150, and 175 shot, with a fuel pressure at 60psi.

#18

Supreme Member

Re: Single-stage Nitrous for the 406 with Holley EFI

You’ve been given good advice, but I’m adding a couple comments for insurance/safety.

Fuel pressure switch – A must, which you said you have, to kill the nitrous if your fuel pressure drops, preventing catastrophic failure.

Window switch – set above the two-step (or your launch rpm) and below the rpm limiter if one. Prevents another catastrophic failure if you hit the nitrous too soon when the two-step is still “active” and cuts it off before getting into the rev limiter.

Internal/Interior nitrous pressure gauge – As already indicated - need to make sure the pressure isn’t too high or low before making a pass – I prefer one with a low/high warning light. I’ll add that if you put the bottle in the spare tire well of a 3rd Gen, the exhaust can heat that area up when there’s no airflow (like on a dyno or long idle periods). Pressure can creep up and exceed the safety mark – will need to be able to see it and bleed off pressure with the purge solenoid. I also prefer running an interior fuel pressure gauge with a built-in warning light set a few pounds under the safety switch cut off pressure – gives a heads up if there’s about to be a problem.

Big in-line nitrous filter – Two approaches here. 1) You can connect it to your bottle when you get it filled to make double sure any trash that may come from the fill bottle is filtered – even if the place has one, you will know you have a clean bottle. 2) If you don’t want the shop to perceive you bringing your own filter as an insult to them, or you think you might need to borrow a bottle at the track, you can put it in-line near the bottle and for easy access. If picking just one, I prefer the later, just in case there happens to be a need to “borrow” a bottle – which I’ve had to do a couple times in my earlier years when I only had one spare - lol.

Timing Retard - I know you’re working on the nitrous retard, but having it kick in with the activation of the solenoid is key.

Nitrous Lines - I never had an issue in over 30-years of building my own (and other’s) nitrous lines (proper PTFE hose). Where you get into trouble here is using different manufactures fittings and lines. Not all PTFE lines have the same size inner thickness of tubing or opening – the olive that sits on the outside of the inner lining and the nipple on the fitting have to be compatible. If you’re having a lot of trouble getting on either the olive or the fitting, then you more than likely have a miss-match.

Example of different manufacturer’s 4AN PTFE hose. IMAGE

General comments

se a true nitrous AN fitting with the filtered screen on the inlet of the nitrous solenoid. If you can’t tell I’m a freak when it comes to making sure no trash finds its way to the spray bar.

When setting up someone else’s carbed nitrous system I always use a small fuel filter at the gas solenoid inlet for the same reasons as above. If you have a good high quality fuel filter already in-line before the “T” and you’re comfortable with the filtering of your fuel system this would be overkill.

I’m fairly certain that not all the NOS plates are the same (could be just the fittings I suppose). However, if I were you, I would check Holley's website to see what if any difference they list for the jetting for a particular HP rating on the PowerShot, Super PowerShot, or Cheater Plate - obviously you would need to know which one you have. Anyway, check the nitrous and gas jet recommendations for the appropriate plate, then use some math to figure out which gas jet you would need for the EFI fuel pressure. When in doubt, go fat at first and begin leaning out by reading the plugs (as other said).

You may want to consider putting the solenoids at the rear of the engine, especially the nitrous solenoid to make it easier to route the purge tubing. As you said, putting everything up front will be tricky and to me seeing a bunch of lines running everywhere isn’t going to be appealing. To me it’s better to not see it or lessen the visibility.

Certainty not an all-inclusive list, but there are a few extra things for you to consider.

HTH

Fuel pressure switch – A must, which you said you have, to kill the nitrous if your fuel pressure drops, preventing catastrophic failure.

Window switch – set above the two-step (or your launch rpm) and below the rpm limiter if one. Prevents another catastrophic failure if you hit the nitrous too soon when the two-step is still “active” and cuts it off before getting into the rev limiter.

Internal/Interior nitrous pressure gauge – As already indicated - need to make sure the pressure isn’t too high or low before making a pass – I prefer one with a low/high warning light. I’ll add that if you put the bottle in the spare tire well of a 3rd Gen, the exhaust can heat that area up when there’s no airflow (like on a dyno or long idle periods). Pressure can creep up and exceed the safety mark – will need to be able to see it and bleed off pressure with the purge solenoid. I also prefer running an interior fuel pressure gauge with a built-in warning light set a few pounds under the safety switch cut off pressure – gives a heads up if there’s about to be a problem.

Big in-line nitrous filter – Two approaches here. 1) You can connect it to your bottle when you get it filled to make double sure any trash that may come from the fill bottle is filtered – even if the place has one, you will know you have a clean bottle. 2) If you don’t want the shop to perceive you bringing your own filter as an insult to them, or you think you might need to borrow a bottle at the track, you can put it in-line near the bottle and for easy access. If picking just one, I prefer the later, just in case there happens to be a need to “borrow” a bottle – which I’ve had to do a couple times in my earlier years when I only had one spare - lol.

Timing Retard - I know you’re working on the nitrous retard, but having it kick in with the activation of the solenoid is key.

Nitrous Lines - I never had an issue in over 30-years of building my own (and other’s) nitrous lines (proper PTFE hose). Where you get into trouble here is using different manufactures fittings and lines. Not all PTFE lines have the same size inner thickness of tubing or opening – the olive that sits on the outside of the inner lining and the nipple on the fitting have to be compatible. If you’re having a lot of trouble getting on either the olive or the fitting, then you more than likely have a miss-match.

Example of different manufacturer’s 4AN PTFE hose. IMAGE

General comments

se a true nitrous AN fitting with the filtered screen on the inlet of the nitrous solenoid. If you can’t tell I’m a freak when it comes to making sure no trash finds its way to the spray bar.

When setting up someone else’s carbed nitrous system I always use a small fuel filter at the gas solenoid inlet for the same reasons as above. If you have a good high quality fuel filter already in-line before the “T” and you’re comfortable with the filtering of your fuel system this would be overkill.

I’m fairly certain that not all the NOS plates are the same (could be just the fittings I suppose). However, if I were you, I would check Holley's website to see what if any difference they list for the jetting for a particular HP rating on the PowerShot, Super PowerShot, or Cheater Plate - obviously you would need to know which one you have. Anyway, check the nitrous and gas jet recommendations for the appropriate plate, then use some math to figure out which gas jet you would need for the EFI fuel pressure. When in doubt, go fat at first and begin leaning out by reading the plugs (as other said).

You may want to consider putting the solenoids at the rear of the engine, especially the nitrous solenoid to make it easier to route the purge tubing. As you said, putting everything up front will be tricky and to me seeing a bunch of lines running everywhere isn’t going to be appealing. To me it’s better to not see it or lessen the visibility.

Certainty not an all-inclusive list, but there are a few extra things for you to consider.

HTH

Last edited by BadSS; 08-30-2021 at 08:21 PM.

#19

Supreme Member

Thread Starter

iTrader: (25)

Join Date: Sep 2005

Location: NJ

Posts: 1,816

Received 280 Likes

on

218 Posts

Car: 1987 IROC-Z

Engine: 406 on N20 w/ EFI

Transmission: P.B. 700R4

Axle/Gears: 12 bolt w/ 3.91

Re: Single-stage Nitrous for the 406 with Holley EFI

BadSS: awesome reply. thank you ! some clarifications and my explanations are listed below

- fuel pressure switch. still on the fence about this one. see my narrative below. Also, I didn't have one with my previous nitrous system on the tpi 305 which I ran nitrous on the street pretty often for a good 6 years, and that was using the stock pump. I know, I know, different pump now, different engine, different lines, different demand. etc. But the Holley sniper can sense a lean condition and instantly kill the nitrous too as a fail-safe.

window switch- Luckily this is a feature involved in the Holley sniper software, and I can set it to whatever rpms I choose with just a couple mouse clicks. I am thinking of only allowing it to spray between 3,500-6,000 rpms. thoughts??

- nitrous pressure gauge. so I currently have a nitrous gauge mounted to the snout of the actual bottle. the bottle is on a NOS bottle mount which positions the bottle in between the rear seats just on top of the driveshaft tunnel. I like it there, as I can turn the bottle on and off from the drivers' sear. It is not in the trunk well, but that is interesting you mentioned about the exhaust heat back there, I had never considered that. I like my bottle where it is on the driveshaft hump, so it is staying there. I can not read the gauge when I am belted into the seat, but I can read the gauge as I get in the car before getting strapped in. If it is high, I can purge it down accordingly before getting strapped in. In the future, It might be something I add a secondary nitrous gauge (and fuel pressure gauge) into an A-pillar gauge cluster, but I definitely do not want to have an excessive amount of gauges in my cabin. Aesthetically, i won't do something like haphazardly mount gauges all over, so i have to figure out a way to make it look good. This would be a winter-time project for me, but it does seem like a great idea if I can find a clean way of doing it.

filter- I had seen those big in-line filters while shopping for my nitrous fittings just a few nights ago. I might add one, but I don't want it to be visible. Its a bit unsightly and this still has to be a street, show, strip, autocross car..not a race car. I have run the small in-line nitrous filters in the past, and i ordered a fresh one (which will arrive tomorrow), but it is not the big kind you suggested.

timing retard- this will all be the responsibility of the holley sniper ecu to do the timing control. However, it is my responsibility to program the timing into the sniper software/tune. In the coming days, i will definitely be posting some screenshots of the holley nitrous tune that I plan to do for my initial testing. Hopefully you (and everyone else) can analyze them and see if I have anything incorrect or in need of adjustment.

lines: yea, I have built a bunch of PTFE lines before. My whole fuel system i did that way. Kept it all one brand too.. like ou mentioned, some companies have different measurements. I ordered ALL of my fuel/nitrous fittings from summit but they are all Earls (holley) and NOS (holley) fittings, so they should play nice together. As for using braided lines; the only braided lines on this whole setup will be the -4 nitrous supply line from the bottle-firewall and to the engine. The rest of the nitrous system wil be 3/16" hard-line that I will bend out of copper nickle, tube nuts, and tube sleeves. The only braided flexible fuel line will be from the fuel tank-body to the engine. The rest will also be the 3/16" hard-line. hard-line will look cleaner, if i can do it neatly.

general - yes, that small -an nitrous filter you mention, thats the one I have. I was going to put it right before the purge solenoid, but now that I think of it, might make more sense to put it in front of the nitrous flow solenoid? I have a pretty stout fuel filter in my system (the magnetic racetronix) one, and I am pretty comfortable that it does its job well. I swapped out the filter element after about 3 years of use (9,000 miles) and it was super clean. I installed a new one anyways, but since the "old" was so clean, I put it in a box and into my spare parts cabinet. Also, yup, see my typing below for the jet info. They arrive tomorrow. I initially wanted the solenoids at the back of the engine bay, but there is definitely no room. It would make future engine work a lot more of a headache. I contemplated my options for a long time, and for my first "version" of nitrous on this engine, I am going to keep them where they are. Maybe one day a new location will be more suitable or possible, and I am willing to experiment, but at this point in time, I kinda want to get this car back up and running asap.

My update

fittings ordered and will arrive tomorrow. There is a lot of them and I am not thrilled about having that may connections to make on the fuel and nitrous systems, but I will take my time and do it as neat/properly as possible. It is a lot though... but that is because I am using 3/16" hard-line. if I was just using the -an braided hoses, there would be less fittings, but then I would have swoopy "messy" lines all curling about in a very confined area. Not desirable for me.

Also ordered some jets after doing some calculations to figure out what will work for a 75 shot, 100, 125, 150 shot. Some of the jets I already have will work too, so I only had to order about 6 jets for now.

Was going to install the Autolite 3923 spark plugs, but I was hesitant to do so after checking the gap on them when I took them out of the box. They appear to be factory gapped at about .038 to .040 and I think that is too big of a gap. probably ok for N/A, but for a small nitrous shot, I would think I should go .030 or so. Thoughts?

Took care of about 95% of the wiring too. Well, actually 100% if I do decide NOT to use the fuel pressure safety switch. If I do decide to use it, I will have to decide if I should wire it in with the (master-arming switch -> ecu) or (momentary switch on the shifter -> ecu) Not sure if it matters, and still not even sure I want to install it. Some of the EFI and nitrous gurus I've talked to elsewhere say that the switch isn't necessary, and other people seem to like having multiple safety features in place. Again, keep in mind, the sniper ecu will instantly kill the nitrous if it reaches my lean-cutoff parameters.

In wiring the nitrous to the ecu, I had to loose my 2-step rev limiter because that occupied my input#2 spot of the 10 pin sniper connector. I'm ok with not having a 2-step as I am just foot brake launching at 1,800 rpms anyway.

- fuel pressure switch. still on the fence about this one. see my narrative below. Also, I didn't have one with my previous nitrous system on the tpi 305 which I ran nitrous on the street pretty often for a good 6 years, and that was using the stock pump. I know, I know, different pump now, different engine, different lines, different demand. etc. But the Holley sniper can sense a lean condition and instantly kill the nitrous too as a fail-safe.

window switch- Luckily this is a feature involved in the Holley sniper software, and I can set it to whatever rpms I choose with just a couple mouse clicks. I am thinking of only allowing it to spray between 3,500-6,000 rpms. thoughts??

- nitrous pressure gauge. so I currently have a nitrous gauge mounted to the snout of the actual bottle. the bottle is on a NOS bottle mount which positions the bottle in between the rear seats just on top of the driveshaft tunnel. I like it there, as I can turn the bottle on and off from the drivers' sear. It is not in the trunk well, but that is interesting you mentioned about the exhaust heat back there, I had never considered that. I like my bottle where it is on the driveshaft hump, so it is staying there. I can not read the gauge when I am belted into the seat, but I can read the gauge as I get in the car before getting strapped in. If it is high, I can purge it down accordingly before getting strapped in. In the future, It might be something I add a secondary nitrous gauge (and fuel pressure gauge) into an A-pillar gauge cluster, but I definitely do not want to have an excessive amount of gauges in my cabin. Aesthetically, i won't do something like haphazardly mount gauges all over, so i have to figure out a way to make it look good. This would be a winter-time project for me, but it does seem like a great idea if I can find a clean way of doing it.

filter- I had seen those big in-line filters while shopping for my nitrous fittings just a few nights ago. I might add one, but I don't want it to be visible. Its a bit unsightly and this still has to be a street, show, strip, autocross car..not a race car. I have run the small in-line nitrous filters in the past, and i ordered a fresh one (which will arrive tomorrow), but it is not the big kind you suggested.

timing retard- this will all be the responsibility of the holley sniper ecu to do the timing control. However, it is my responsibility to program the timing into the sniper software/tune. In the coming days, i will definitely be posting some screenshots of the holley nitrous tune that I plan to do for my initial testing. Hopefully you (and everyone else) can analyze them and see if I have anything incorrect or in need of adjustment.