Did your machine shop use torque plates?

#1

Did your machine shop use torque plates?

For those who had their LS motors rebuilt, did your machine shop use torque plates? If not, how's your motor holding up?

My local machine shop has a very, very good reputation. He does the machine work for, well, pretty much everybody around here, including all the guys that restore cars and race cars. He doesn't have torque plates for the LS motors, and has also said that you flat out don't need them. He even offered to mic the cylinders of one of the SBC motors he had around with and without the torque plates to show me that there's virtually no measurable difference. With the head bolt design on LS motors, I'd expect even less of a difference. He also reminded me that GM didn't use torque plates when they honed these motors. My motor had 130k on it and the cross hatch pattern looked brand new when I pulled it apart. where's there room for improvement with torque plates?

All of the guys on LS1tech keep saying to find a different machine shop, but this guy has an outstanding reputation... and the closest machine shop WITH torque plates is 1-2 hours away, and I know nothing of their reputation.

What would you do?

My local machine shop has a very, very good reputation. He does the machine work for, well, pretty much everybody around here, including all the guys that restore cars and race cars. He doesn't have torque plates for the LS motors, and has also said that you flat out don't need them. He even offered to mic the cylinders of one of the SBC motors he had around with and without the torque plates to show me that there's virtually no measurable difference. With the head bolt design on LS motors, I'd expect even less of a difference. He also reminded me that GM didn't use torque plates when they honed these motors. My motor had 130k on it and the cross hatch pattern looked brand new when I pulled it apart. where's there room for improvement with torque plates?

All of the guys on LS1tech keep saying to find a different machine shop, but this guy has an outstanding reputation... and the closest machine shop WITH torque plates is 1-2 hours away, and I know nothing of their reputation.

What would you do?

#2

Re: Did your machine shop use torque plates?

he doesn't have stock small block ford torque plates? I wouldn't build a higher hp setup without them. If it's going to be a mild buildup then it's less of an issue, but ALL my setups gets done that way. Maybe you should drive the extra time or just ship it to someone who has stepped into the world of modern engine builds.

#3

Supreme Member

Join Date: Mar 2004

Location: In the Garage

Posts: 2,519

Likes: 0

Received 4 Likes

on

3 Posts

Car: Camaro

Engine: 6.2L

Transmission: T56

Re: Did your machine shop use torque plates?

Its not such a huge issue with aluminum blocks. Aluminum is more stable and doesn't shrink/expand/contract etc nearly as much as iron does. Adding torque plates in no way can hurt however and if a shop that builds stuff swears by them well so be it. Not all shops build the same way... Heck look at what Smokey Yunick used to do. Everyone thought he was insane cutting engines in half and whatnot using his "farmer technology" but he built some of the most durable, fastest engines ever in his day.

To make a long story longer here I'd trust the reputation of a well known shop over the opinions of someone who knows not of the work done there. Reputation and referrals are everything IMO especially if the shop has been around longer than 10 yrs that says a TON right there IMO. Not many survive yet they may be the biggest thing going at the time...

Wheel to wheel? for instance...

Anyways good luck. Curious how big are you going that you want to bore? Are you adding sleeves? How much RPM are you after?

To make a long story longer here I'd trust the reputation of a well known shop over the opinions of someone who knows not of the work done there. Reputation and referrals are everything IMO especially if the shop has been around longer than 10 yrs that says a TON right there IMO. Not many survive yet they may be the biggest thing going at the time...

Wheel to wheel? for instance...

Anyways good luck. Curious how big are you going that you want to bore? Are you adding sleeves? How much RPM are you after?

#4

Supreme Member

iTrader: (2)

Join Date: Dec 2006

Location: Hou. TX

Posts: 5,538

Likes: 0

Received 0 Likes

on

0 Posts

Car: 86 TA, 91 B4C

Engine: 5.3, 4.8

Transmission: 4L80 4000, T56

Axle/Gears: 4.30 M12, 23.42 10 bolt

Re: Did your machine shop use torque plates?

Nope, i have a machine shop that tells me it wont matter, torque plate honing the block will keep the distortion away...tilly uo remove the torque plate and bolt the head on, then it is out again, so he basically says there is no point, but my OTHER machine shop says otherwise, unless you are building a pro stock engine, it isnt worth your time.

#5

Supreme Member

iTrader: (2)

Join Date: Feb 2006

Location: 39.84N 105.11W

Posts: 1,547

Likes: 0

Received 0 Likes

on

0 Posts

Car: '89 Trans Am GTA

Engine: WAS 350 - now L92 (alum. 378/6.2L)

Transmission: WAS 700R4, now a built T56

Axle/Gears: 3.27 9-bolt

Re: Did your machine shop use torque plates?

Originally Posted by cam-

Its not such a huge issue with aluminum blocks. Aluminum is more stable and doesn't shrink/expand/contract etc nearly as much as iron does.

Uhhh, cam-, I don't think that I've had any significant disagreements with you the whole time I've been here, but I'm having a real hard time going along with you on this one. My understanding is that aluminum has a significantly higher rate of thermal expansion/contraction than iron does. (Rumor has it that there's a metallurgist around here somewhere who could give us the definitive answer...)

Uhhh, cam-, I don't think that I've had any significant disagreements with you the whole time I've been here, but I'm having a real hard time going along with you on this one. My understanding is that aluminum has a significantly higher rate of thermal expansion/contraction than iron does. (Rumor has it that there's a metallurgist around here somewhere who could give us the definitive answer...)

But hell, I've been wrong before...

I think that as far as the 'torque plates' issue goes, both sides could be right -

You could bore & hone an engine without using them, & it'd be just fine - shops built engines that way for YEARS - but performing the same operation with a torque plate will result in a bore that's more accurate (by a few percentage points) & will likely last a little bit longer than one bored without a torque plate.

At least, that's my understanding...

Last edited by V8Rumble; 02-24-2010 at 09:56 PM.

#6

Senior Member

Join Date: Sep 2009

Location: Madison, SD

Posts: 569

Likes: 0

Received 0 Likes

on

0 Posts

Car: '82 Camaro

Engine: 383

Transmission: TKO 5 speed

Axle/Gears: 31 spline 9" with 4.56:1

Re: Did your machine shop use torque plates?

If they don't use plates they wouldn't be doing the bore and hone on my block..... Maybe he doesn't think they're necessarey, but I do.... Maybe I'm just too fussy.

#7

Supreme Member

Re: Did your machine shop use torque plates?

The idea behind the torque plate is that it puts the distortion on the bore that the head would, so when you bolt the heads on, it gets pulled to where the torque plate had it.

the way I see it, if bolting the head on is going to make that much of a difference then your shop needs to heat the block to operating temperature to account for that too.

the way I see it, if bolting the head on is going to make that much of a difference then your shop needs to heat the block to operating temperature to account for that too.

Trending Topics

#9

Supreme Member

iTrader: (2)

Join Date: Feb 2006

Location: 39.84N 105.11W

Posts: 1,547

Likes: 0

Received 0 Likes

on

0 Posts

Car: '89 Trans Am GTA

Engine: WAS 350 - now L92 (alum. 378/6.2L)

Transmission: WAS 700R4, now a built T56

Axle/Gears: 3.27 9-bolt

Re: Did your machine shop use torque plates?

Originally Posted by Apeiron

There are plenty of shops that do that, too.

Yep - the way I understand it, that's not especially uncommon either...

Yep - the way I understand it, that's not especially uncommon either...

#10

Re: Did your machine shop use torque plates?

Let's assume for a minute that I get this built without the torque plates. What am I really giving up here? A couple horsepower due to a slight decrease in ring seal? What are we talking about here, 1-2, maybe 5 hp? What about reliability? The stock bores look brand new at 130k miles, and GM didn't use torque plates, so how much more wear could I possibly see this time around? Maybe it'll only go 300k miles instead of 350k miles?

I really don't see how I'm going to benefit that much from the torque plates... but I just wish there were a few guys out there that got their motors built without them who could chime in.

Reputation and referrals are everything IMO especially if the shop has been around longer than 10 yrs that says a TON right there IMO.

Last edited by Jim85IROC; 02-25-2010 at 07:18 AM.

#11

Re: Did your machine shop use torque plates?

Even heating a block does not simulate the great temperature gradient that develops in a running engine.

The plate honing process wasn't developed for efficient street motors. It was developed for endurance racing, and then just adopted by machine shops as an extra service to offer for other builds.

With endurance racing, the extra friction and heat from continuous high RPM operation is a factor. Even though plate honing might only make a couple horsepower difference at high RPM, the reduced friction is significant where it comes to heat build-up in the piston, and "could" make a difference in an endurance race.

This practice is along the same lines as align honing.

It's an effort to reduce friction by a small amount that could make a real difference for an engine that sees continuous high RPM.

For a street engine it is highly unlikely that you could measure any difference in power, even on an engine dyno, that would fall outside the range of repeatability.

The operations on a street engine sure don't hurt anything if done correctly, but I wouldn't expect a significant bonus there either.

I think your machine shop was being honest with you.

That said, torque plates don't cost all that much to buy. The shop might give you a deal on machine work if you acquired them a plate for LSX.

I would check with Goodson or Pioneer to see if they sell that plate.

The plate honing process wasn't developed for efficient street motors. It was developed for endurance racing, and then just adopted by machine shops as an extra service to offer for other builds.

With endurance racing, the extra friction and heat from continuous high RPM operation is a factor. Even though plate honing might only make a couple horsepower difference at high RPM, the reduced friction is significant where it comes to heat build-up in the piston, and "could" make a difference in an endurance race.

This practice is along the same lines as align honing.

It's an effort to reduce friction by a small amount that could make a real difference for an engine that sees continuous high RPM.

For a street engine it is highly unlikely that you could measure any difference in power, even on an engine dyno, that would fall outside the range of repeatability.

The operations on a street engine sure don't hurt anything if done correctly, but I wouldn't expect a significant bonus there either.

I think your machine shop was being honest with you.

That said, torque plates don't cost all that much to buy. The shop might give you a deal on machine work if you acquired them a plate for LSX.

I would check with Goodson or Pioneer to see if they sell that plate.

#12

On Probation

Join Date: Oct 2008

Location: Northern Utah

Posts: 6,319

Likes: 0

Received 17 Likes

on

17 Posts

Car: seeking '90.5-'92 'bird hardtop

Engine: several

Transmission: none

Axle/Gears: none

Re: Did your machine shop use torque plates?

I've dynoed a pair of LS1s, one deck plated for hot honing, the other cold honed with no plate. Everything else identical. The pre-fire torque to rotate them differed by less than 10 inch-pounds. Then after run-in, the output was within 3.3 ft-lbs and 4.3 hp. That was nearly 3 years ago. Since then, neither has developed any issues at all.

Use of deck plates for honing an Lsx are bragging rights, nothing more. On a Ford 302 block, they do make a worthwhile difference, but not for any version of the LSx.

Anyone who tells you otherwise either is going on hearsay or stands to profit from you having it done.

Use of deck plates for honing an Lsx are bragging rights, nothing more. On a Ford 302 block, they do make a worthwhile difference, but not for any version of the LSx.

Anyone who tells you otherwise either is going on hearsay or stands to profit from you having it done.

#13

Supreme Member

Join Date: Mar 2004

Location: In the Garage

Posts: 2,519

Likes: 0

Received 4 Likes

on

3 Posts

Car: Camaro

Engine: 6.2L

Transmission: T56

Re: Did your machine shop use torque plates?

Uhhh, cam-, I don't think that I've had any significant disagreements with you the whole time I've been here, but I'm having a real hard time going along with you on this one. My understanding is that aluminum has a significantly higher rate of thermal expansion/contraction than iron does. (Rumor has it that there's a metallurgist around here somewhere who could give us the definitive answer...)

Uhhh, cam-, I don't think that I've had any significant disagreements with you the whole time I've been here, but I'm having a real hard time going along with you on this one. My understanding is that aluminum has a significantly higher rate of thermal expansion/contraction than iron does. (Rumor has it that there's a metallurgist around here somewhere who could give us the definitive answer...)

But hell, I've been wrong before...

I think that as far as the 'torque plates' issue goes, both sides could be right -

You could bore & hone an engine without using them, & it'd be just fine - shops built engines that way for YEARS - but performing the same operation with a torque plate will result in a bore that's more accurate (by a few percentage points) & will likely last a little bit longer than one bored without a torque plate.

At least, that's my understanding...

I still stand by the comments that the shops reputation is much more important than their process.

For example.... Some of the best body men I've ever seen still use lead and their work lasts for decades....

Know who I'd ask Jim is Katech. They build some durable stuff

#14

Re: Did your machine shop use torque plates?

Thanks for the info guys. That gives me a lot of peace of mind with choosing the local guy. Now I need to get my block down to him and have him verify that there's still enough material in the bores to just hone to .005

#15

Member

Re: Did your machine shop use torque plates?

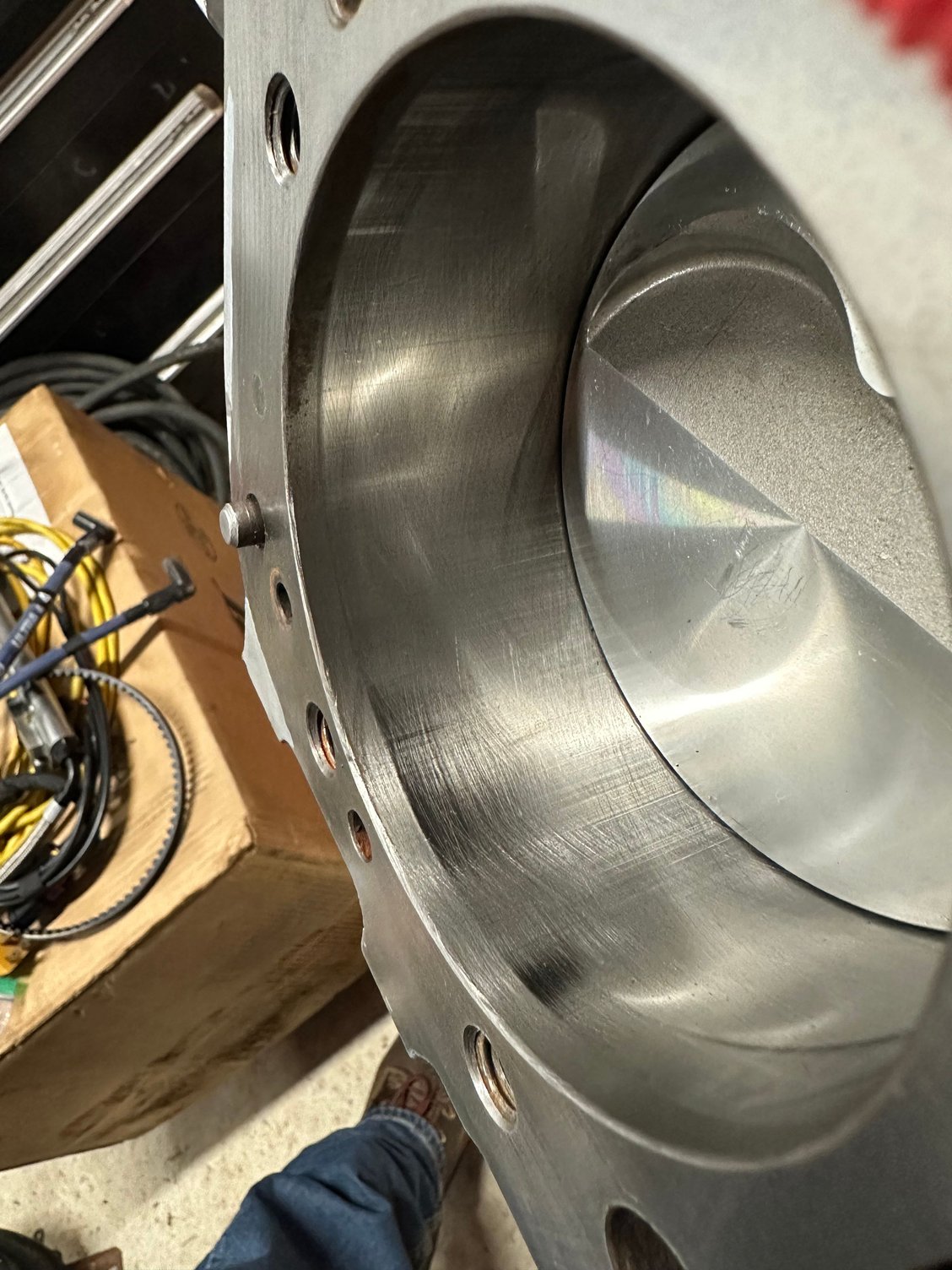

See those dark marks in the cylinder bores adjacent to the bolt holes?

I machined this block with arp head bolts and torque plate honed it, after using the bolts for honing, mock up and assembly the bolts failed and I changed to head studs and they required more torque and ran the motor on the run stand. Needless to say the head studs were problematic and leaking so I pulled the heads changed the head gaskets and switched back ARP bolts and discovered the dark spots and itís definitely attributed to distortion under torque. Some was my problem because I switched to studs after honing, moral of the story torque plate honing with same fasteners is a must and proves the fact that doing honing without them on a stock block anything will have the same results.

#16

Junior Member

Re: Did your machine shop use torque plates?

Tom, thank you for your pictures and description of what happened. I'm old school and even almost 40 yrs ago I knew that torque plates were a must for proper honing. I wouldn't use a machine shop that didn't use torque plates.

This is an old thread but the information is still relevant today.

This is an old thread but the information is still relevant today.

#17

Supreme Member

iTrader: (8)

Join Date: Oct 2001

Location: Il

Posts: 11,723

Received 773 Likes

on

520 Posts

Car: 1989-92 FORMULA350 305 92 Hawkclone

Engine: 4++,350 & 305 CIs

Transmission: 700R4 4800 vig 18th700R4 t56 ZF6 T5

Axle/Gears: 3.70 9"ford alum chunk,dana44,9bolt

Re: Did your machine shop use torque plates?

On a engine where the bolts/studs are right into the deck, I'd probably use the plates for a mild and up build.

now with the LS engine and long head bolts, that changes things and is exactly why they went with longer bolts. Looking for thinner rings/better ring seal cheaper costs made the changes happen

now with the LS engine and long head bolts, that changes things and is exactly why they went with longer bolts. Looking for thinner rings/better ring seal cheaper costs made the changes happen

#18

Junior Member

Re: Did your machine shop use torque plates?

TTOP, I didn't know that about the longer bolts in the LS engines. That makes sense to me and I feel that i learned something.

I still like the idea of the torque plates no matter what. Anything to simulate as much as possible, any distortion that is going to manifest itself when bolts/studs are tightened up.

I still like the idea of the torque plates no matter what. Anything to simulate as much as possible, any distortion that is going to manifest itself when bolts/studs are tightened up.

The following users liked this post:

TTOP350 (10-01-2023)

Thread

Thread Starter

Forum

Replies

Last Post